16

imperfections. Also, pipes should be capped to prevent

contaminant during shipping, storage, etc.

•

Antifreeze solution is very lubrise and difficult to seal

compared to plain water and initial care in pipe connections

will minimize leaks at start-up. Also, antifreeze solution will

prevent microbiological attack to piping material 5 times

greater than water. Cleanliness is required to improve

longevity of solution. Prefabricated pipe should be capped

during shipping and staging prior to installation.

•

If grooved couplings are utilized in the system piping

installation, "flush seal" gaskets, low temperature EPDM

rubber and lube are required. Pooling of propylene glycol in

the system shall be eliminated. Vent valves shall be

minimum ½” ball valves with ½” plug. Vent valves can

double as solution test points as well; the Viking Model AV-1

Air/Vent Valve is recommended, as it includes strainer and

test connection for automatic venting during fill and drain of

the system. Material installed on the system shall be

compatible with propylene glycol solution. A re-claim tank

with adequate capacity of the largest system(s) shall be

located near the system riser(s). System drain piping shall

be arranged to discharge to the re-claim tank.

5.1.2 Primary Check Valve Main Drain

The main drain outlet should be

directed to an appropriate

location, and the drain valve shall

be installed at an accessible level

so it can be operated from the

floor level. Installing the isolation

Easy Riser

TM

Check valve at an

elevation near the horizontal

mains supplying the system and

10 to 15 ft (3,0 to 4,5 m) above the

primary check valve will reduce the cold thermal transfer of propylene

glycol solution in the system piping to the vertical system riser and

minimize frosting on the system riser.

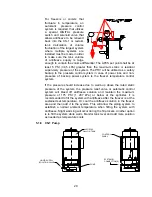

The main drain valves from the isolation check and primary check valves

shall be installed at an accessible level, as the solution will be trapped in

the drop leg to the drain valve and will not affect the total calculation for

the system. The main drain valve will be used to drain the system piping

downstream of the Easy Riser

TM

Check Valves. As the cold antifreeze

from the freezer area will emit cold thermal transfer, it will be required to

insulate the drain pipe to prevent frosting.

Summary of Contents for ESFR

Page 5: ...5 Figure 1 Straight Through Configuration...

Page 6: ...6 Figure 2 Angle Style Configuration...

Page 10: ...10...

Page 35: ...35...