6. Loosely attach mounting brackets to the countertop, parallel to

the cutout opening using the supplied mounting screws and

nuts. Mounting screws with brass inserts are supplied with the

sink, however, countertop material vary and the correct type of

fasteners should be recommended by your installer or supplier.

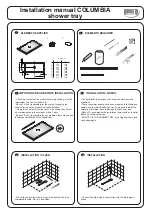

7. Clean sink flange and underside of cutout area of countertop,

making sure that the area is smooth and free of grease. MUST

use 100% silicone for this installation. Apply continuous bead

of silicone caulk evenly on top of sink flange. (FIGURE 4)

NEVER perform this procedure outdoor and under sunlight.

If performed under an extremely hot and dry climate, the

caulking of the sink frame should be performed by two

people at the same time.

8. Position and align sink over the countertop opening and press

sink onto countertop. Turn bent end of mounting bracket to

snug over the sink rim.

9. Check alignment of sink again and tighten fasteners to secure

sink. (FIGURE 5)

10. Wipe away excess silicone caulk with damp cloth. Connect

drain and water supply according to manufacturer's instruction.

Figure 4

Figure 5

4