iii

Declaration of RoHS2 Compliance

This product has been designed and manufactured in compliance with Directive

2011/65/EU of the European Parliament and the Council on restriction of the use

of certain hazardous substances in electrical and electronic equipment (RoHS2

Directive) and is deemed to comply with the maximum concentration values issued

by the European Technical Adaptation Committee (TAC) as shown below:

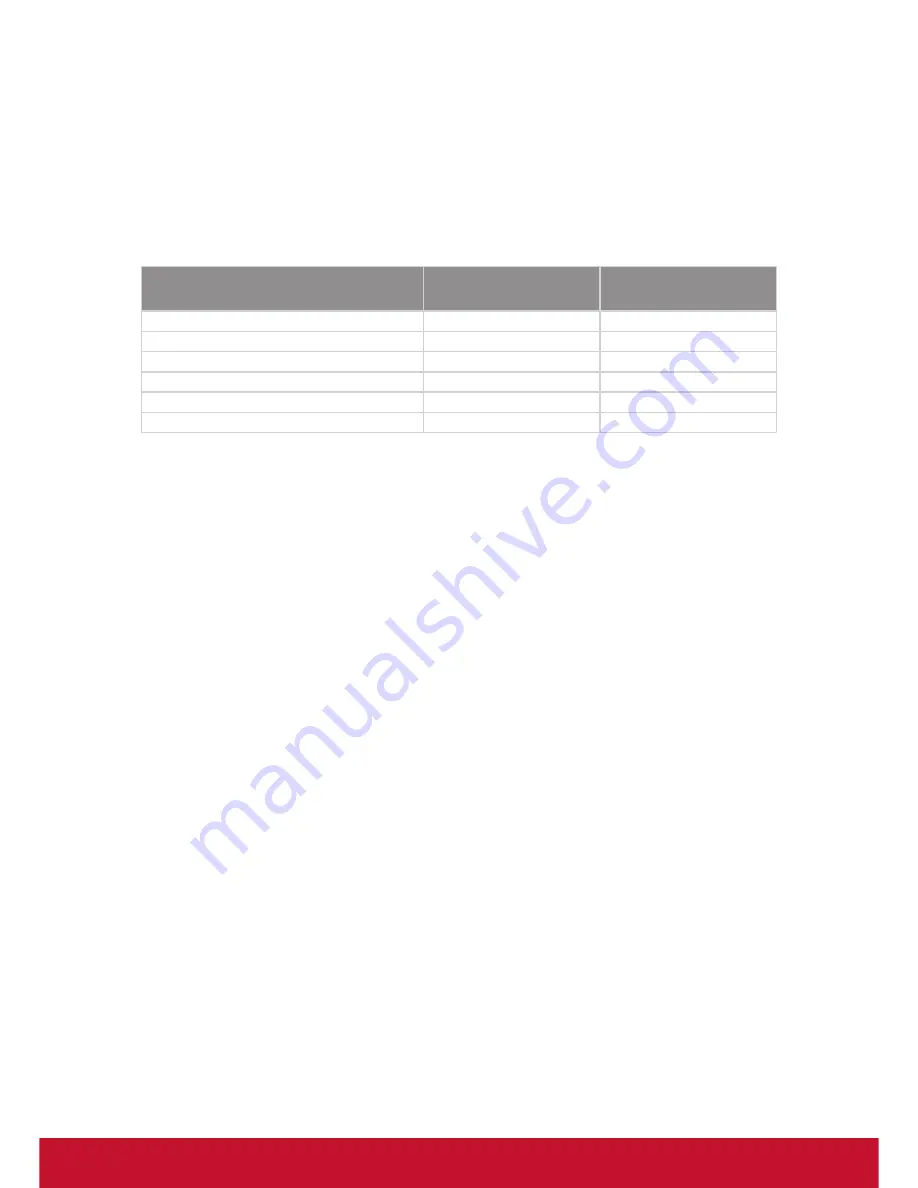

Substance

Proposed Maximum

Concentration

Actual Concentration

Lead (Pb)

0.1%

< 0.1%

Mercury (Hg)

0.1%

< 0.1%

Cadmium (Cd)

0.01%

< 0.01%

Hexavalent Chromium (Cr6+)

0.1%

< 0.1%

Polybrominated biphenyls (PBB)

0.1%

< 0.1%

Polybrominated diphenyl ethers (PBDE)

0.1%

< 0.1%

Certain components of products as stated above are exempted under the Annex III

of the RoHS2 Directives as noted below:

Examples of exempted components are:

1.

Mercury in cold cathode fluorescent lamps and external electrode fluorescent

lamps (CCFL and EEFL) for special purposes not exceeding (per lamp):

(1) Short length (

≦

500 mm): maximum 3.5 mg per lamp.

(2) Medium length (

>

500 mm and

≦

1,500 mm): maximum 5 mg per lamp.

(3) Long length (

>

1,500 mm): maximum 13 mg per lamp.

2.

Lead in glass of cathode ray tubes.

3.

Lead in glass of fluorescent tubes not exceeding 0.2% by weight.

4.

Lead as an alloying element in aluminium containing up to 0.4% lead by weight.

5.

Copper alloy containing up to 4% lead by weight.

6.

Lead in high melting temperature type solders (i.e. lead-based alloys containing

85% by weight or more lead).

7.

Electrical and electronic components containing lead in a glass or ceramic other

than dielectric ceramic in capacitors, e.g. piezoelectronic devices, or in a glass or

ceramic matrix compound.