Rev. 6/23/2021

STRAP-WALL MANUAL

Copyright 2021 Vestil Manufacturing Corp Page 5 of 7

LOADING STRAP MATERIAL

The retaining discs are multi-tiered to accept 16” x 3”, 16” x 6”, or 8” x 8” spools of either steel or

polyester strapping material. The following steps describe how to load a spool into the spool holding

mechanism.

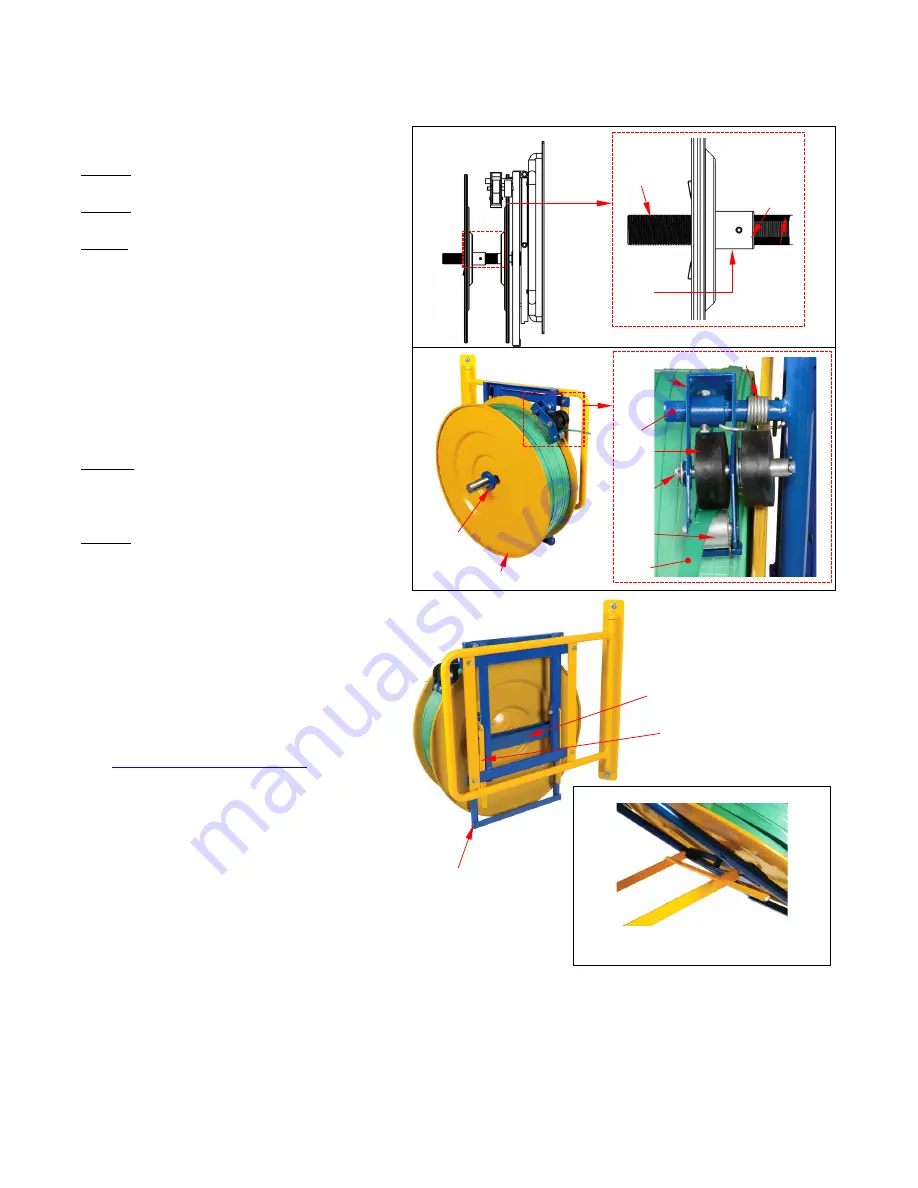

Step 1: Inspect the unit according to the

instructions on p.5.

Step 2: Unwind the wing nut and remove

the outer retaining disc.

Step 3: Install a selected spool of strapping

material. Orient the spool with the strapping

wound counterclockwise around the spool.

Center the core of the spool on the

threaded rod. Install the rod extension if the

spool of strapping material is wider than 3

inches. To install the extension, wind the rod

coupler onto the end of the threaded rod

and tighten the set screw. Refer to FIG. 1.

NOTE

: The threaded rod will

accommodate spools up to 3 inches

wide.

Step 4: Feed the end of the strapping

material between the upper and lower

rollers of the guide wheel assembly (45-645-

003) as shown in FIG. 2.

Step 5: Reattach the outer retaining disc

and wing nut.

DISPENSING STRAP MATERIAL

Slowly and steadily pull the free end of

the strapping material to dispense it. The

spool holding mechanism (inner and outer

discs and threaded rod) will rotate. Do

not pull quickly and forcefully on the end

of the strap or the spool holder will over

rotate and dispense too much strapping.

To change spools of strapping, follow

on p. 5.

The spool holding assembly can be

used in either of 2 configurations: vertical

and inclined. To incline the assembly, pull

the bottom of the spool frame (45-514-015)

away from the wall. Lift the bottom end of

the yellow support stand (45-514-017). Prop

the free ends of the support stand against

the middle cross brace of the spool frame.

RECORD OF SATISFACTORY CONDITION

Record the condition of the device before putting it into service for the first time. Include

observations about the spool retaining discs, welds, frame elements (frame, support stand, safety chain,

quick link, snap hook, wheels, guide wheel assembly, and strap dispensing mechanisms (collectively

“features”). Thoroughly photograph the unit so that all features are clearly imaged. Take close range

photographs of all labels applied to the unit. Add the photographs to the record. Describe where each

label is located. Collect all photographs and writings in a file. This file is a record of the device in

satisfactory condition. During future inspections, compare your observations to the

RECORD

to

determine if the unit is in satisfactory condition.

FIG. 1

FIG. 2

Rod

extension

Set

screw

T

hreaded

rod

Rod

coupler

Upper

roller

Wing nut

(blue)

Outer retaining disc

Roller

bracket

Roller

pin

Guide wheel

assembly

Spring

Lower

roller

Strap

INCLINED CONFIGURATION

Prop ends of support stand against

middle brace of spool frame

Spool frame

(45-514-015)

Support stand

(45-514-017)

Middle cross

brace

VERTICAL

CONFIGURATION

Guide

wheel

peg