Rev. 11/18/2019

LAD-EZ (6-12 STEPS), MANUAL

Copyright 2019 Vestil Manufacturing Co.

Page 4 of 20

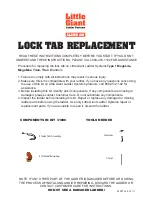

FIG. 1: Foot Lock Mechanism Exploded View and Bill of Materials

Part no.

Description

Quantity

11055

5

/

16

in. – 18 x 1in. HHCS #2 zinc-plated bolt

2

11061

5

/

16

in. – 18 x 2in. HHCS #2 zinc-plated bolt

4

11105

3

/

8

in. – 16 x 1in. hex head bolt

2

26329

3

/

8

in. shoulder x

3

/

4

in. x

5

/

16

in. – 18

2

33006

5

/

16

in. USS zinc-plated flat washer

2

33456

1

1

/

8

in. I.D. 10 gauge machine bushing

2

36106

3

/

8

in. – 16 zinc-plated hex nut

2

37024

3

/

8

in. Nylock insert nut

4

65127

3

/

16

in. x 2in. zinc-plated cotter pin

2

20-027-005 Roller guide

4

28-146-003 Spring

2

44-514-354 Weldment, frame, caster pivot foot lock “caster

bracket”

1