Rev. 4/17/2019

FE MANUAL

Copyright 2019 Vestil Manufacturing Corp. 5 of 6

B. At least once per month:

Inspect each extension for warps, bends, and cracks.

Closely inspect the tine lock/loop for damage.

Verify that all welds are intact.

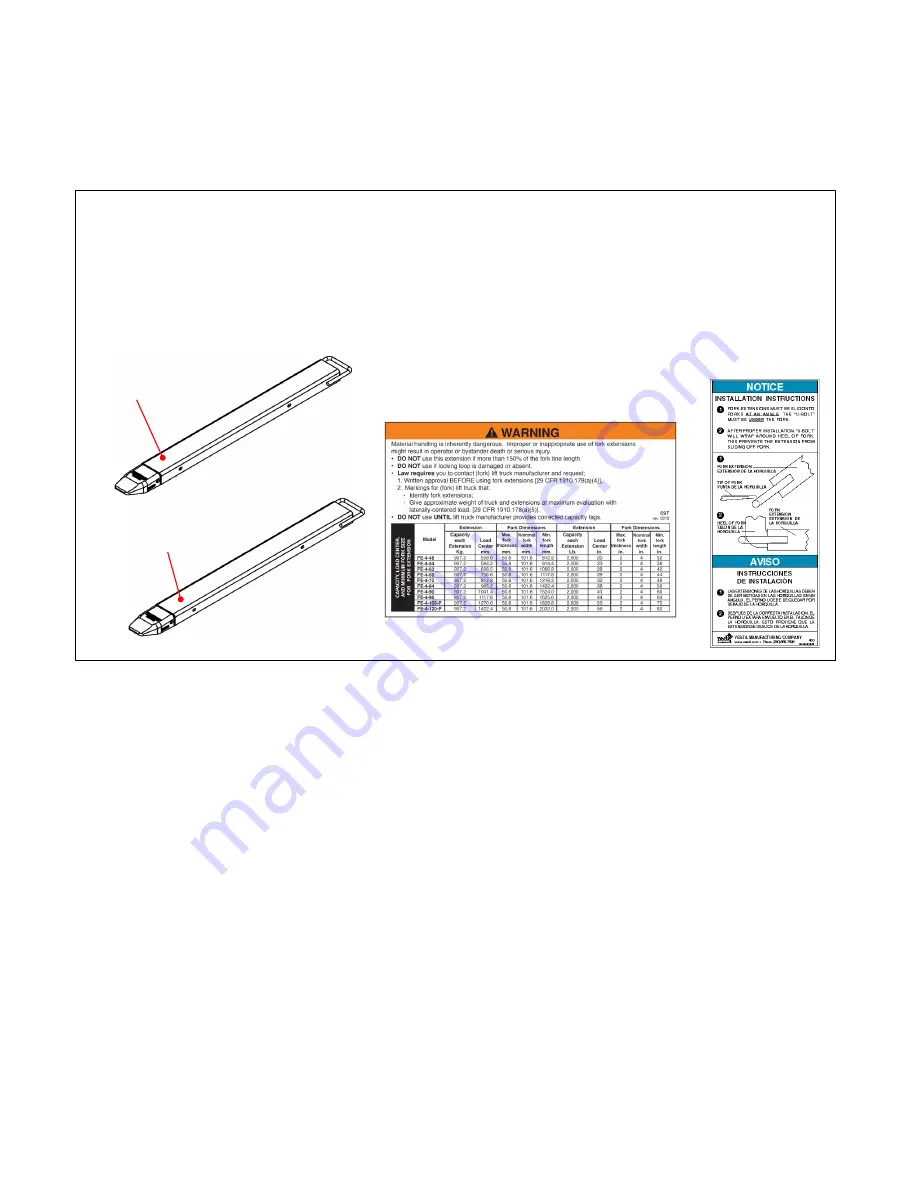

Confirm that each label is located as shown in the

and readable.

A: Label 697 (FE-4); 698 (FE-5); 699 (FE-6);

1047 (FE-7); or 1048 (FE-8)

B: Label 460

B

(on underside

near tip)

A

(on underside

near tip )

Labeling diagram:

Each pair of extensions should be labeled as shown in the diagram. However, label content and

location are subject to change so your product might not be labeled exactly as shown. Replace all

labels that are damaged, missing, or not easily readable (e.g. faded). To order replacement labels,

contact the technical service and parts department online at

http://www.vestilmfg.com/parts_info.htm

Alternatively, you may request replacement parts and/or service by calling (260) 665-7586 and

asking the operator to connect you to the