Rev. 4/17/2019

FE MANUAL

Copyright 2019 Vestil Manufacturing Corp. 4 of 6

Installation:

You should obtain a copy of the most recent edition of ANSI/ITSDF B56.1

BEFORE

installing, using, or maintaining your fork extensions.

Confirm Proper Fit:

Using fork extensions that are too long or too wide, or both, is dangerous. After receiving your

extensions you should confirm that they properly fit your forklift. If you have any questions about the fit of

. DO NOT use the extensions unless they properly fit the

forks of your forklift.

1. Compare the length of the forks (also called tines) to the length of the fork extensions. The extensions

must not be more than 150% of the length of the forks.

2. Review labeling applied to the underside of your extensions. The warning label provides important

information about the minimum and maximum dimensions of forks that could be used with the

extension.

3. To prevent the extensions from moving side-to-side during use, select a model that matches the fork

width. According to ANSI/ITSDF B56.1-2005, paragraph 7.39.5, p. 51, for a fork extension to fit a fork

properly, “Lateral clearance shall not exceed 12mm between fork and extension.”

Record of Normal Condition:

Before putting the extensions into service, make a written record that thoroughly describes the

condition of each one. Describe welds, hardware (if applicable), and paint/powder coat. Determine the

levelness of each extension, e.g. with a bubble level. Photograph the unit from several vantage points.

Add the photographs to the record. Include photographs of all labels applied to the unit. Indicate where

the labels are applied. This record establishes normal condition. Compare your observations during all

inspections to this record to determine if the unit is in normal condition or requires repair. Purely cosmetic

changes, e.g. damaged paint/powdercoat, are not changes from normal condition. However, touchup

paint should be applied wherever the finish is damaged as soon as the damage occurs.

Inspections:

Compare the results of all inspections to the

Record of Normal Condition

.

A. Before each use:

Look for damage to either the fork extension or the tine lock/loop. Verify that the locking

mechanism functions normally.

Examine the tip of the extension. Make sure that it is not cracked or deformed, and that the

weld between the tapered end and the fork pocket portion is intact.

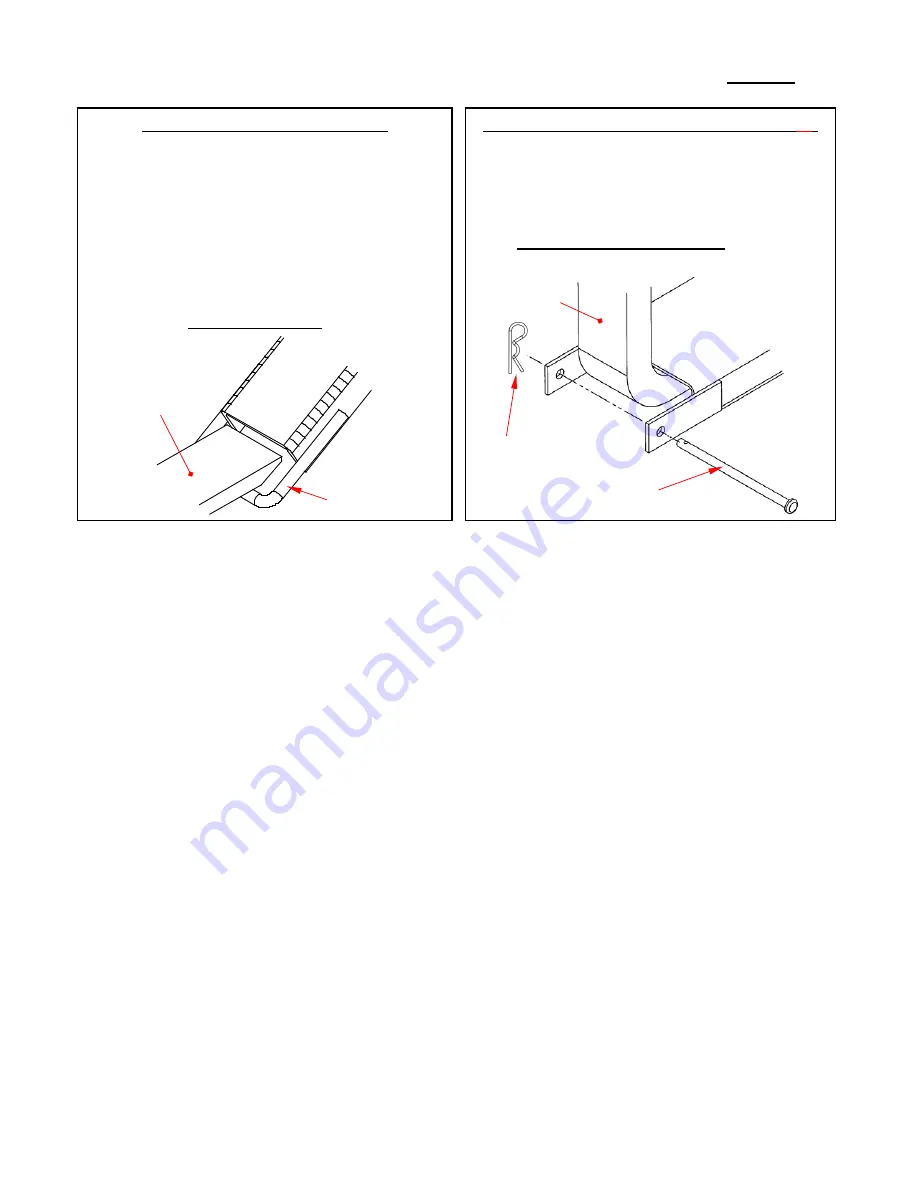

Removable Pin Tine Lock (Models FE-x-xx

-P

)

Remove the R-pin and pull out the lock pin.

Place the fork extension over the tine/fork.

Install the locking behind the heel of the tine;

then reinstall the R-pin.

Standard Welded-Loop Tine Lock

Raise the forks (tines) approximately 4-6in. from

the ground. Manually lift the tip of the fork

extension so that the extension is angled at 45°

to the ground/floor. Guide the tine loop

underneath the tapered end of the tine; slide the

fork extension onto the tine until it reaches the

heel of the tine; then lower the extension onto

the fork once the tine lock is behind the heel of

the tine.

Standard tine loop

Tine lock with removable pin

Tine loop

Fork / Tine

Fork

extension

Lock pin

(14-612-001)

R-pin

(45286)

Fork / tine

Fork

extension