14

N.B.

x

Too high an input level will burn the coil

x

If the source material has an extremely wide dynamic

range, minimum levels may not be sufficient to achieve

the desired result. In this case, use of Vestax SL-201mkii

compressor-limiter is required.

13. Using anti-static spray, clean the vinyl blank perfectly.

14. Set external music source at the desired start

point in pause or stop mode

15. Lock the cutting arm by rotating the cam. Manually move

the arm by using manual rotation wheel and position arm

above appropriate point on blank.

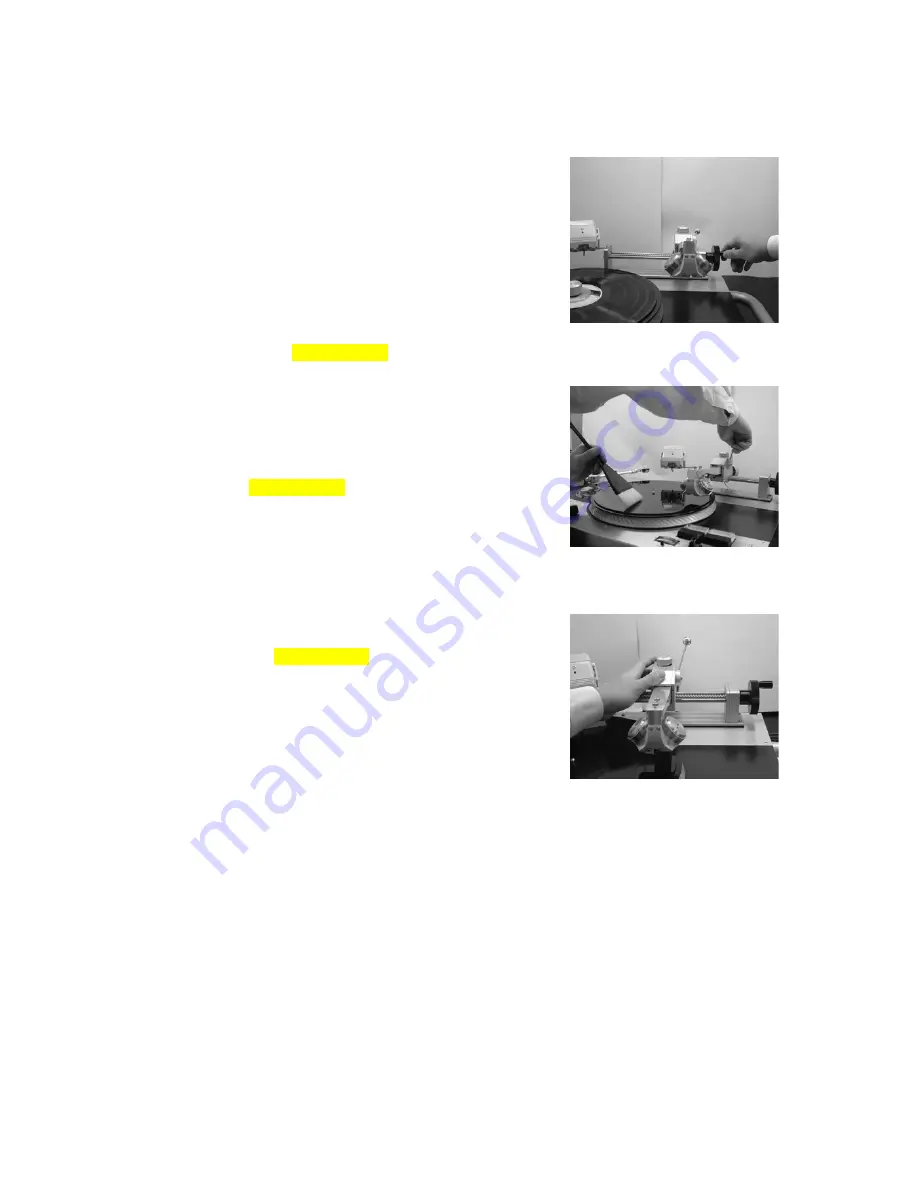

16. Hold the brush as per (Figure 12.1-C).

Place the release lever in the down position gently.

17. Start the music source and recording begins!

18. Using the brush gently take the excess vinyl

off-cuts away form the cutting stylus.

Try to make the vinyl off-cuts wind around the center

spindle (disc holder). This will reduce the amount

of brush action required.

Please refer to (Figure 12.1-D).

Caution: If the vinyl off-cuts builds up around the

cutting stylus you will not get a perfect cutting result.

Please continually check the stylus. In case the

off-cuts get stuck around the stylus use the tweezers

to remove the build up very carefully.

19. Put the input level down as you would with a fade out

on an audio mixer.

20. Move the release lever gently to the up position, then

unlock the cam. Move the arm all the way to the right

away from the vinyl(Figure 12.1-E).

21. Push Start/Stop button to stop the platter rotation.

22. Check the surface of the vinyl and check there are

no off-cuts on the vinyl. If there is any residual, use

the record cleaner and cleaning solution to clean the vinyl.

FIG12.1D

FIG12.1C

FIG12.1E