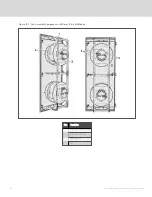

Item

Description

1

System low pressure tap

2

System high pressure tap

3

Bottom supply connection to heat load

4

Bottom return connection from heat load

5

System fluid fill connection

6.5.1 Fluid Fill Source

The fluid fill source for the system may be from a municipal utility source or pumped in manually or by use of a transfer

pump from a portable fluid receptacle and provide 10-12 psig.

Guidelines:

•

Pump should be capable of 15 psi (30 feet H2O) max head.

•

Elevate the fluid receptacle above the pump to provide net positive suction head (NPSH) required by pump.

•

Prime the pump and hoses to avoid pump damage and minimize the introduction of air to the system.

•

Place free end of the bleed hose into the fluid receptacle to minimize loss of treated fluid.

•

Follow transfer pump manufacturer’s instructions for duty cycle, net positive suction head, and priming

requirements.

Figure 6.4 Transfer Pump Fill General Arrangement

6 Piping Requirements

31

Summary of Contents for Liebert XDU 060

Page 1: ...Liebert XDU Liquid to Air Heat Exchanger for Chip Cooling Installer User Guide 600 mm Wide ...

Page 10: ...Vertiv XDU Liquid to Air Heat Exchanger for Chip Cooling 6 This page intentionally left blank ...

Page 38: ...Vertiv XDU Liquid to Air Heat Exchanger for Chip Cooling 34 ...

Page 74: ...Vertiv XDU Liquid to Air Heat Exchanger for Chip Cooling ...