CFDV Series Gas Fireplace

12

20306739

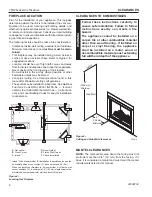

INSTALLATION PRECAUTIONS

Consult local building codes before beginning the

installation. The installer must make sure to select the

proper vent system for installation. Before installing vent

kit, the installer must read this fi replace manual and vent

kit instructions.

Only a qualifi ed installer/service person should install vent-

ing system. The installer must follow these safety rules:

•

Wear gloves and safety glasses for protection.

•

Use extreme caution when using ladders or when on

rooftops.

•

Be aware of electrical wiring locations in walls and

ceilings.

The following actions will void the warranty on your vent-

ing system:

•

Installation of any damaged venting component.

•

Unauthorized

modifi cation of the venting system.

•

Installation of any component part not manufactured

or approved by Vermont Castings Group.

•

Installation other than permitted by these instruc-

tions.

VENTING INSTALLATION

W

ARNING

Read all instructions completely and

thoroughly before attempting installation.

Failure to do so could result in serious injury,

property damage or loss of life. Operation

of improperly installed and maintained

venting system could result in serious injury,

property damage or loss of life.

NOTICE

Failure to follow these instructions will

void the warranty.

Do not pack the open air spaces with

insulation or other materials. This could

cause high temperatures and may present

a fi re hazard.

W

ARNING

This fireplace must be vented to the

outside. The venting system must NEVER

be attached to a chimney serving a separate

solid fuel burning appliance. Each gas

appliance must use a separate vent system.

Do not use common vent systems.

W

ARNING

GENERAL VENTING

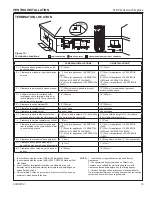

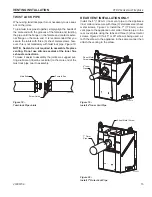

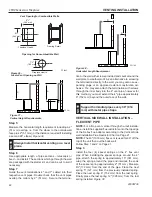

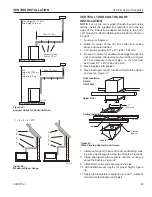

Your fi replace is approved to be vented either through the

side wall, or vertical through the roof.

•

Only Vermont Castings Group venting components

specifi cally approved and labeled for this fi replace

may be used.

•

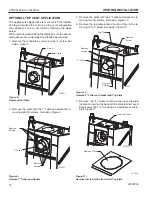

Flexible UL1777 listed venting may be used in any vent-

ing application where rigid direct vent components can

be used. All restrictions, clearances and allowances that

pertain to the rigid piping apply to the fl exible venting.

Flex kits may not be modifi ed. Flex kits may be added to

the end of a vent run made of rigid vent sections using

pipe manufacturer's approved fl ex to pipe adapters. This

may occur only if doing so does not violate any of the

venting length, height, routing, horizontal to vertical ratio

requirements or clearance considerations detailed in this

manual.

•

Venting terminals shall not be recessed into a wall or sid-

ing.

•

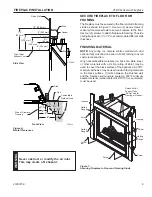

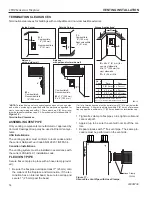

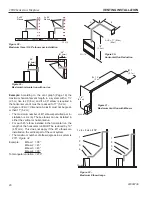

Select the amount of vertical rise desired. All horizontal

run of venting must have 1/4" rise for every 12" (305 mm)

of run towards the termination below 7

1

/

2

feet of vertical

rise. With 7

1

/

2

feet (2.3 m) or more vertical rise off top of

fi replace, the horizontal run may run level. NEVER run

vent piping downward.

•

Horizontal venting which incorporates the twist lock pipe

must be installed on a level plane without an inclining or

declining slope.

•

Horizontal venting which incorporates the use of fl ex

venting shall have an inclining slope from the unit of 1"

(25 mm) per 24" (610 mm).

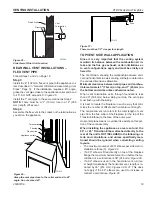

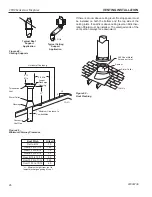

There must not be any obstruction such as bushes, gar-

den sheds, fences, decks or utility buildings within 24"

(610 mm) from the front of the termination hood.

Do not locate termination hood where excessive snow or

ice build up may occur. Be sure to check vent termina-

tion area after snow falls, and clear to prevent accidental

blockage of venting system. When using snow blowers,

make sure snow is not directed towards vent termination

area.

Location of Vent Termination

It is imperative the vent termination be located observing

the minimum clearances as shown on following page.