21

Operation & maintenance manual, Drum filter HDF 12/16/20/24 -series

8. MAINTENANCE/SERVICE

8.1 Backwash system

The most common cause of disruption in the wash water system is nozzle clogging. Clogging is

caused by particles in the wash water and/or by e.g. biological fouling in the pipe system.

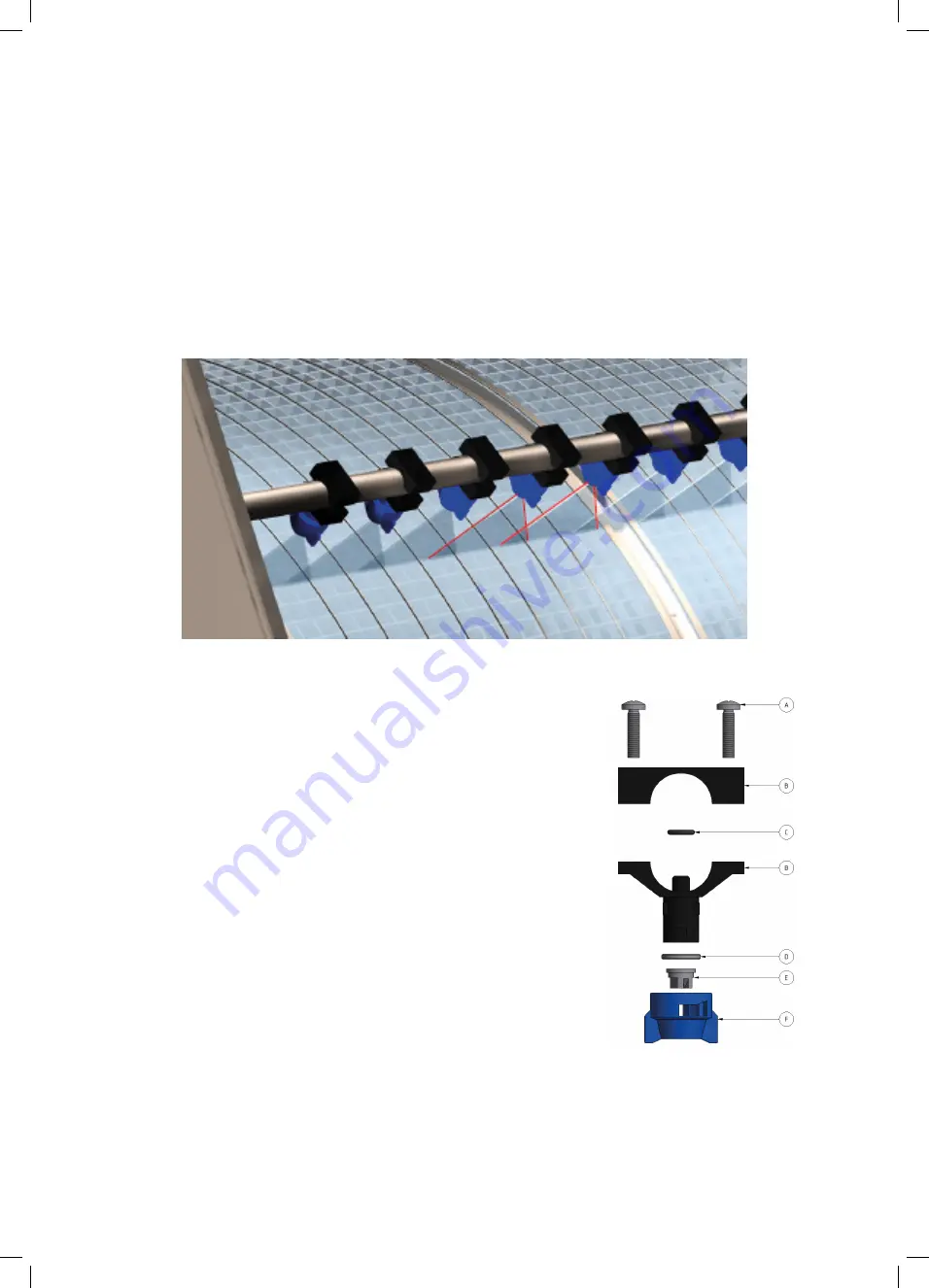

The correct dispersal pattern is shown below for wash water. Clogged nozzles can produce a dif-

ferent dispersal pattern.

There are also nozzles that are self-cleaning and less sensitive to blocking than the conventional

nozzles, see section 8.1.2.

8.1.1 Servicing conventional nozzles

1. Turn the main power switch to the OFF (0) position and the mode

selector to the 0 (OFF) position. If the used backwash water supp-

ly unit is not from Hydrotech, ensure that the supply of backwash

water is turned off.

2. Remove the covers on the side where the backwash pipe is loca-

ted.

3. Ensure that none of the nozzles are clogged by checking whether

water runs through them.

4. Remove the nozzle nut of a clogged nozzle by turning it a ¼ turn

anticlockwise. Exercise care so as not to lose the rubber seal.

5. Clean the tip of the nozzle with compressed air or with a plastic

brush. Never use a steel brush or metal pins as these may damage

the nozzle.

Figure 8.1 Correct dispersal pattern for wash water

Figure 8.2 Nozzle components:

A. Screws

B. Nozzle attachment

C. O-ring

D. Rubber seal

E. Nozzle tip

F. Nozzle nut