8

VUT 160/250/350 PB EC

www.ventilation-system.com

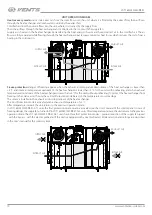

The unit has the following operating logic: warm stale extract air from the room flows into the unit, where it is filtered by the extract filter,

then air flows through the heat exchanger and is exhausted outside by the extract fan. Cold fresh air from the outside flows into the unit,

where it is cleaned by the supply filter.

Then the air flows through the heat exchanger and is directed to the room with the supply fan. Heat energy of warm extract air is

transferred to clean intake fresh air from the outside and warms it up. The air flows are fully separated while flowing through the heat

exchanger. Heat recovery minimizes heat losses, which reduces the cost of space heating in the cold season.

The difference between the supply and extract air flow temperature leads to condensate generation. Condensate is collected in the drain

pan and is removed outside through the drain pipe.

UNIT DESIGN

1

10

11

12

10

13

14

2

3

4

5

9

6

7

8

1 – cable glands; 2 – supply fan; 3 – control unit; 4 – bypass damper; 5 – extract filter; 6 – counter-flow heat exchanger; 7 – drain pan; 8 –

detachable plates for technical maintenance of filters; 9 – drain pipe; 10 – duct electric preheater connector; 11 – extract fan; 12 – supply

filter; 13 – duct electric reheater connector (for VUT 160/250/350 PB EC A21 units); 14 – SETUP MODE button (for VUT 160/250/350 PB EC

A21 units).

Additional equipment (is not included in the delivery set, can be ordered separately)

Humidity sensor.

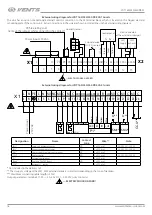

The HV2 humidity sensor is connected to the controller in VUT 160/250/350 PB EC A21 models, and to the terminal block in

VUT 160/250/350 PB EC A14 models. The HR-S humidity sensor is connected to the controller. The unit with the installed humidity sensor

maintains a set indoor humidity point. As the extract air humidity rises above the set point, the system automatically switches to the

maximum speed. As the humidity drops down below the set point the unit returns to the previous mode.

CO

2

sensor

(connected to the controller)

Measures the level of concentration of carbon dioxide in the room and generates a signal that controls the performance of the fan. Air

capacity control based on CO

2

concentration is an efficient energy saving solution.

VOC sensor

(connected to the controller)

Qualitative assessment of air saturation with contaminants (cigarette smoke, exhaled air, solvent and detergent vapours).

The sensor sensitivity can be adjusted with regards to the expected maximum level of air pollution.

Enables on-demand ventilation which results in considerable energy savings as air is exchanged only upon reaching the preset level of

pollution.

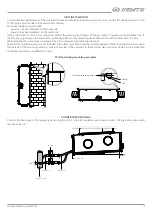

Duct preheater.

The heater maintains the duct air temperature at a point that prevents the heat exchanger freezing. Heater installation and connection

to the unit are described in the heater user’s manual.

Duct reheater.

The heater maintains the room temperature set by the user. Heater installation and connection to the unit are described in the heater

user’s manual.

UNIT DESIGN AND OPERATING PRINCIPLE