HEI240 Wood Insert Fireplace Installation and Operation Manual

29

8

Clearances to Combustible Material

The clearances shown in this section have been determined by test according to

procedures set out in safety standards ULC S628 (Canada), UL1482 (U.S.A.) and UL737

(U.S.A.).

When the insert is installed so that its surfaces are at or beyond the minimum clearances

specified, combustible surfaces will not overheat under normal and even abnormal

operating conditions.

No part of the insert may be located closer to combustibles than the minimum

clearance figures given.

8.1

Location of the Certification Label

Since the information given on the certification label attached to the appliance always

overrides the information published in any other media (owner’s manual, catalogues,

flyers, magazines and/or web sites), it is important to refer to it in order to have a safe and

compliant installation. In addition, you will find information about your insert (model, serial

number, etc.). You can find the certification label to the front on the outside of the air jacket

of the insert.

To access the certification label, the faceplate may need to be removed. Therefore, we

recommend that you note the insert’s serial number on this manual, since it will be needed

to precisely identify the version of the appliance in the event you require replacement parts

or technical assistance.

8.2

The Masonry Fireplace Throat Damper

If the fireplace's draft control system is to remain in the masonry fireplace, it must be

locked open for access of the chimney liner or removed entirely. If you remove draft control

system from the masonry hearth, you will need to install the metal plate (27009), supplied

with the owner’s manual kit, indicating that the masonry hearth has been modified. It must

be secured inside the masonry hearth, in a visible place and easy to locate.

8.3

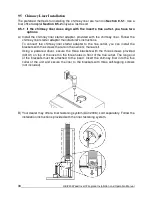

Installation of a Combustible Mantel Shelf

It is possible to install a combustible shelf with a maximum depth of 12" at a height of at

least 27" above the insert. At a height of more than 27 ", the shelf must still have a depth

of 12" maximum. Refer to the following figure.