5.0 Maintenance

9

5.1

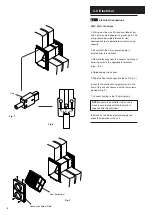

Cleaning the Unit

1. To ensure optimum performance, the unit

should be inspected every 6 months for build up

of dust or debri and washed every 12 months or

at periods determined by the level of

contamination experienced and according to the

following procedure.

2. Isolate the mains power supply.

3. Undo the four securing screws and remove

the connection spigot plate (Fig. 10).

4. Slide out the heat exchanger (Fig 10). The

heat exchanger should be washed in warm

soapy water and dry thoroughly.

5. Reassemble in reverse order ensuring the

heat exchanger is seated correctly.

6. Switch power supply on and check the

operation of the unit.

NOTE:

In heavy polluted internal

environments it is recommended that internal

grilles are fitted with simple washable filters

(ESG150). These filters should be removed

and washed on a regular basis (1-3 months)

or as conditions dictate.

Fig. 10

Heat Exchanger

Connection Spigot Plate