System Setup Screens

Alpha Keypad Screen

11

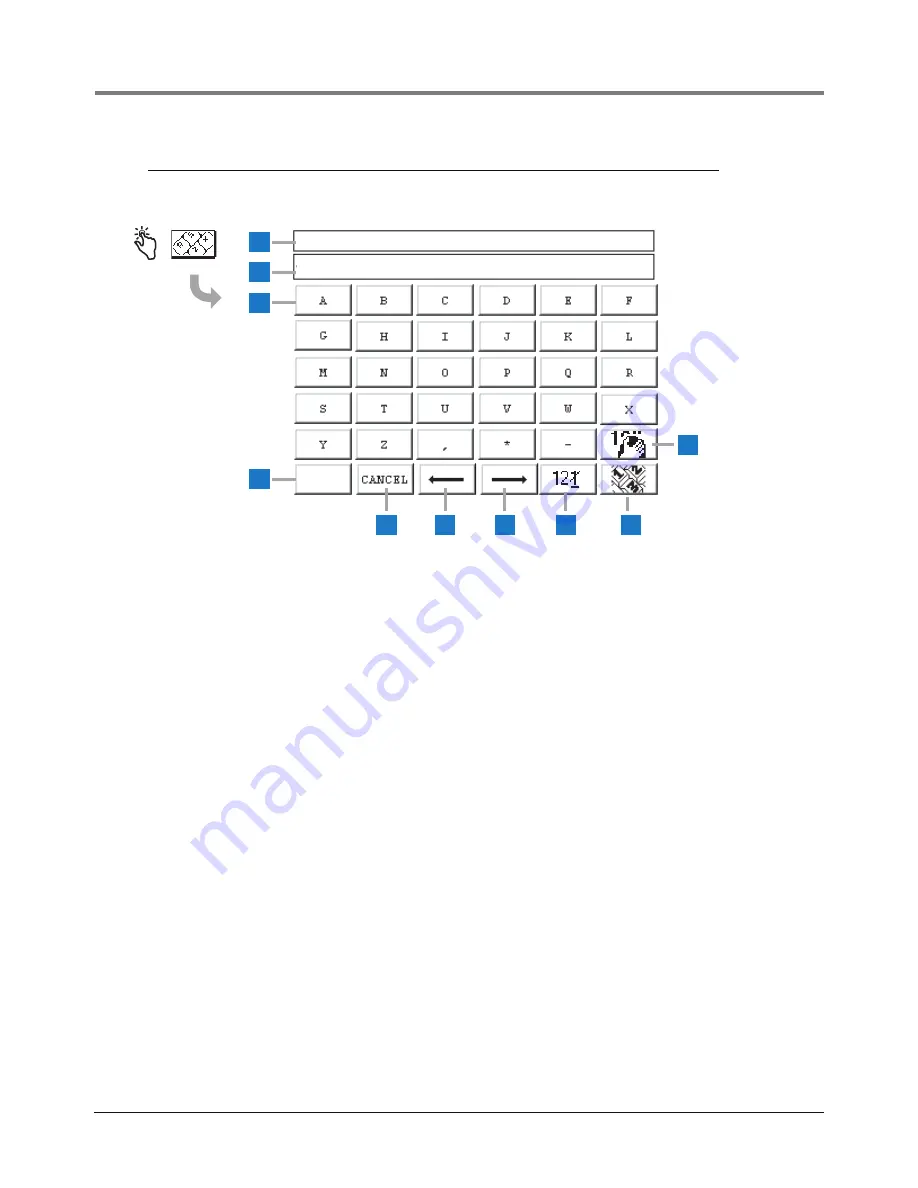

Alpha Keypad Screen

Legend for numbered boxes

1

2

3

4

5

6

7

8

9

10

SAVE

ENTER: STATION HEADER 1

JOHNS MOBIL

1

Displays Title of data to be entered.

2

Data Entered Window displays data entered.

3

Alpha keypad buttons - touch a character button to

place that character in the data entered window (2).

4

Save button - touch to accept entered data and close

Screen.

5

Cancel button - touch to cancel any entry and close

Screen.

6

Cursor left button - touch to move the cursor one

position left in the Data Entered Window (2).

7

Cursor right button - touch to move the cursor one

position right in the Data Entered Window (2).

8

Backspace delete button - touch to delete character in

cursor.

9

Number keypad button - touch to display the Numeric

Keypad Screen.

10

Clear button - touch to clear contents of Data Entered

Window (2).