PI Thermostat TEF

V1.3a, 20100504

© Vector Controls GmbH, Switzerland

Page 5/8

Subject to alteration

Control Function

Temperature Control Mode: PI Control E2=0

The controller reads the temperature either by using its integrated temperature sensor or by using an external

sensor. The controller maintains the temperature set point by calculating the position of the actuator using a 3-

point modulating signal. The on/off actuator is positioned based on its opening and closing time. The

temperature is controlled using a PI control function. If both P and I parts are enabled, they will be added

together to calculate the output position. Following control parameters decide the function of the PI loop:

•

E3: P-band in °K. The p-band corresponds to the temperature difference of current value to setpoint,

which is required for fully opening the output.

•

E4: A large I part increases the swinging tendency of the control loop. Limiting the integral part may

reduce this tendency. The I-part is disabled if 0 is selected.

•

E5: Tn, Reset time of Analog loop integral. Tn is the time needed for the integral to run from 0 to 100%.

The range is 0.5 - 30 min. The setting very much depends on the application it is used for. For

temperature control of a medium sized room, a setting of 5 minutes should be appropriate.

•

P5: Dead Zone Span. The cooling setpoint W

C

consists of the heating setpoint and the dead zone span.

Changing the cooling setpoint therefore changes as well the heating setpoint. The factory setting for the

dead zone span is 1K.

T Room

Temperature

w

H

Setpoint Heating

Xp

E3: Proportional Band

w

C

Setpoint Cooling

Y

T

Output signal of temperature loop

X

DZ

P5: Dead Zone Span

Tn

E5: Integral Reset Time

Switching frequency

The TEF works with two digital outputs to modulate a floating actuator. The position of the actuator is calculated

with above described PI algorithm. The controller moves the actuator to the calculated position by either

opening or closing the actuator. The actuator should not be moved for every little change in position, since this

would reduce the lifetime of the actuator. We differentiate if we are moving the actuator in the same direction

as the previous move or if we reverse direction.

•

E7: Switching difference: For example the last actuator movement was opening and we open again. The

actuator will only move, if the difference to the current actuator position is larger than this parameter.

•

E6: Reversing difference: For example the last actuator movement was opening and we want to close

now. The actuator will only move, if the difference to the current actuator position is larger than this

parameter.

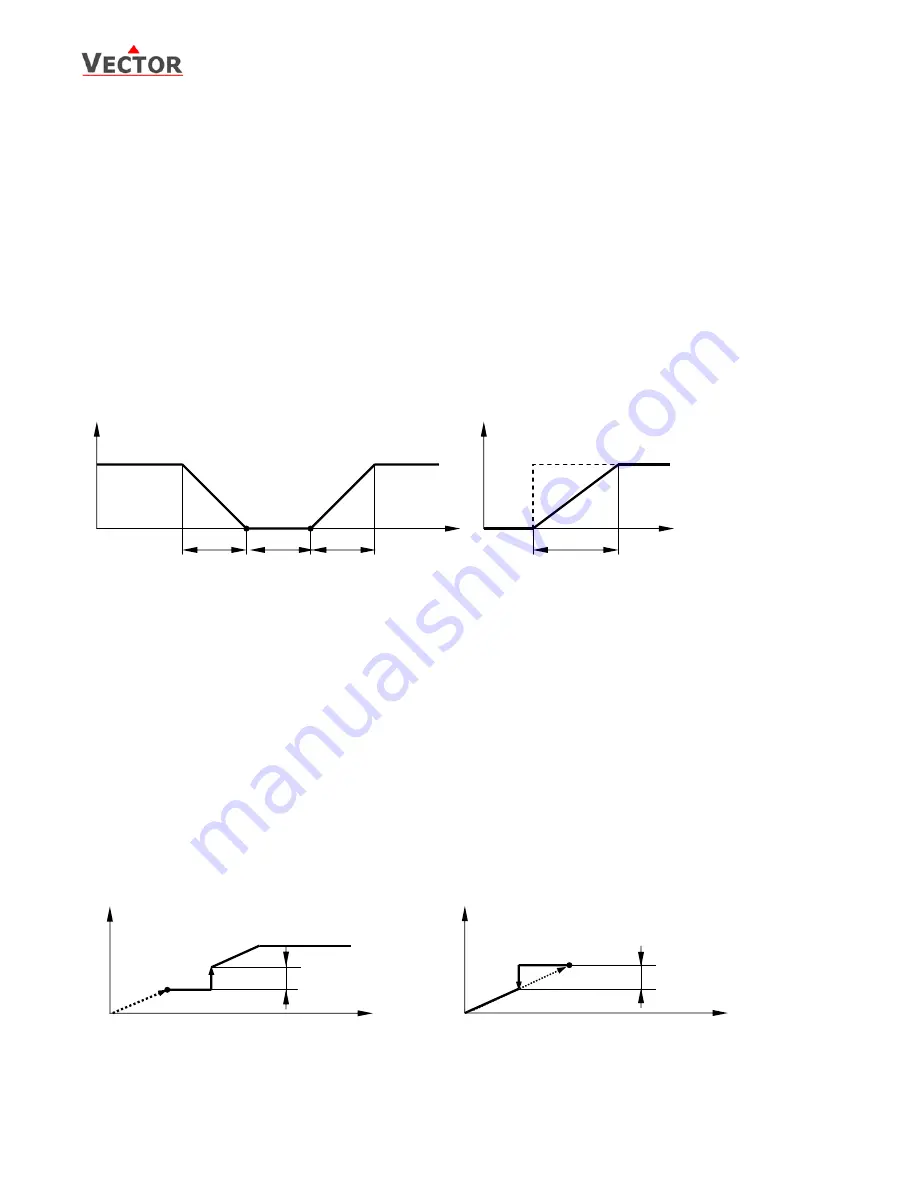

Below are examples of switching and reversing difference after the actuator has been opening on its

previous move.

X

T

Calculated actuator position

RD E6: Reversing Difference

Y

T

Actual actuator position

1

Opening up to step 1

SD

E7: Switching Difference

2

Actuator acting point

Y

T

[%]

100

0

SD

Switching Difference

X

T

[%]

Y

T

[%]

100

0

RD

Reversing Difference

X

T

[%]

1

2

2

1

Y

T

[%]

100

0

Xp

W

H

Xp

W

C

Heating Mode P Control Part Cooling Mode

T [°C]

Y

T

[%]

100

0

Tn

W

H/C

I Control Part

t [min]

X

DZ