Maintenance and Service

3-4

b

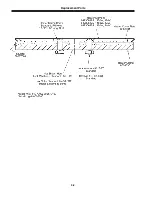

Insert the jet base, making sure the ejector is aligned with the foreline (a keyway in the jet

base will assure alignment). Assemble the remaining stages of the jet. Make sure that all

stages are firmly seated and that all drip shields are in place.

c

Install the cold cap assembly.

3-6

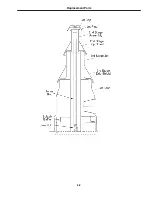

HEATER REPLACEMENT

a

Turn off the power to the diffusion pump and disconnect the power supply.

b

Remove the heater cover and the insulation from the bottom of the diffusion pump.

c

Label the heater wires for proper location during installation.

d

Disconnect the terminal leads. Use two wrenches when loosening these nuts to prevent

breaking the heater terminals.

e

Remove the nuts holding the heater clamp.

f

Lower the entire heater unit from the pump.

g

Replace the defective heater.

h

Assemble the heater, the crush plate, and the clamping plate as a unit.

j

Coat the boiler studs with an antiseize compound such as FEL-PRO C5A or common milk of

magnesia.

k

Support the heater unit by the clamping plate, line up the hole with the boiler stud, and push

the unit up against the boiler plate. Use two nuts, tightened finger-tight, to hold it in place.

l

Secure the remainder of the nuts finger-tight, then tighten the bolts evenly to a torque of 250

inch-pounds.

m

Replace the heater insulation and the cover.

3-7

ADDING PUMP FLUID

The recommended fluid charge for the VHS-6 diffusion pump is 500 cc. The fluid charge will gradually be

depleted through use, but the pump will continue to operate normally. When the charge is reduced to

approximately 60 percent of the initial fill amount, the boiler plate temperature may begin to rise. Under

this condition, the thermal switch, when properly connected, is designed to open the heater circuit.

a

Turn off the power to the pump.

b

Allow the pump to cool until the temperature of the pump body, measured one inch above the

heater skirt, has cooled to 130 degrees F.

c

Vent the pump to atmosphere.

d

Loosen and remove the fill plug located at the top of the sight glass assembly.

e

Add pump fluid until the fluid level is even with the FULL/COLD mark on the sight glass.

f

Replace the O-ring in the fill plug and lubricate it with pump fluid.

g

Install the fill plug and tighten it moderately.

h

Evacuate the diffusion pump and start it following the procedures outlined in previous sections.

Summary of Contents for VHS-6

Page 27: ...Replacement Parts 5 2 ...

Page 28: ...Replacement Parts 5 3 ...