TECHNICAL INFORMATION

13. Turbopump

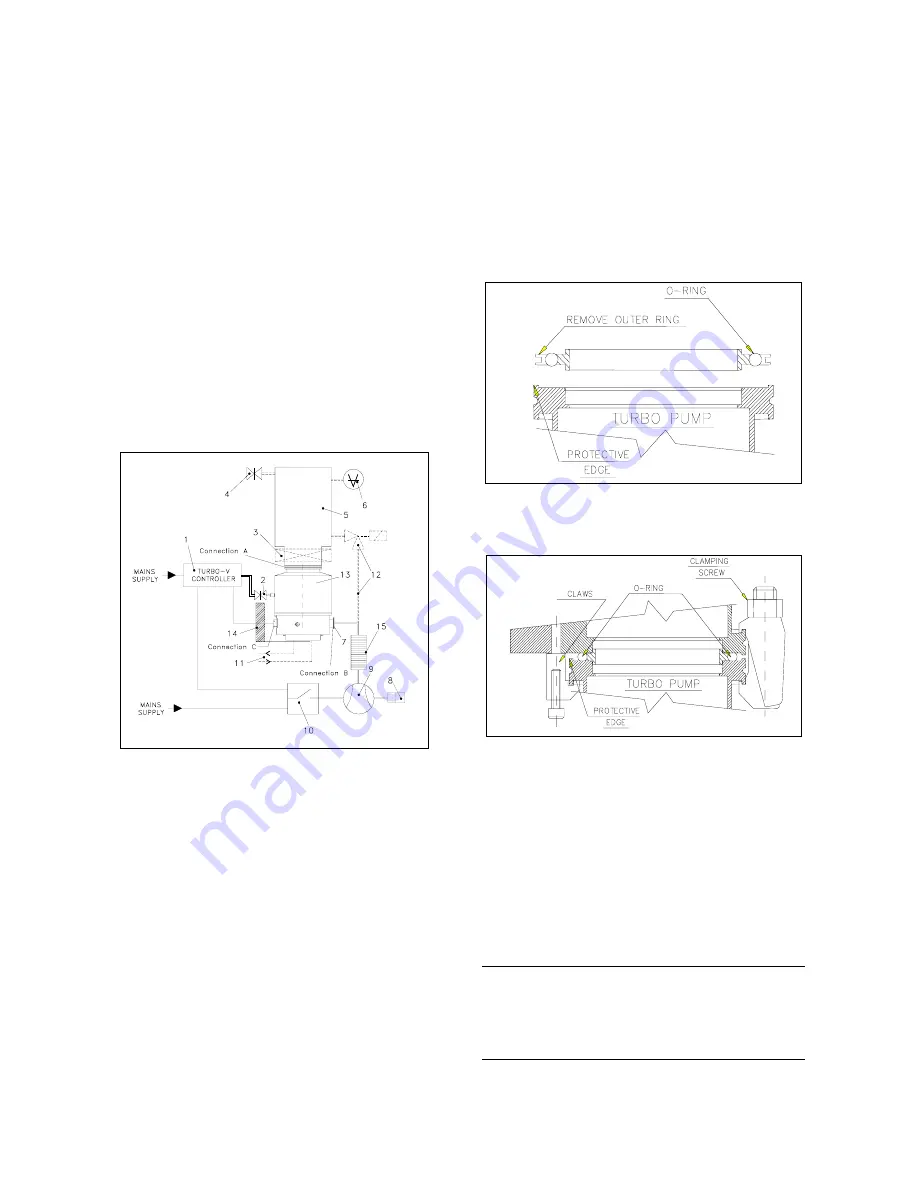

VIBRATION ISOLATOR INSTALLATION

Four vibration isolators for ISO and CFF inlet

flange version pumps are available as accesso-

ries.

14. Fan

15. Flexible connection

The four model part numbers are the following:

Connection A - HIGH VACUUM FLANGE

−

model 969-9342 for ISO 100 flange;

To connect the Turbo-V550 pump to the ISO inlet

flange, remove the outer ring and position the cen-

tering ring as shown in the figure.

−

model 969-9343 for ISO 160 flange;

−

model 969-9332 for CFF 6” flange;

−

model 969-9333 for CFF 8” flange.

They typically reduce the vibration transmitted

from the Turbo-V550 pump to the system by a fac-

tor of 20.

Please refer to the relevant instruction manual.

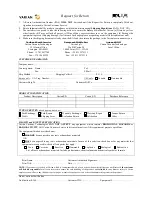

TYPICAL LAYOUT DIAGRAM

Then fix the two flanges with the clamps or claws

as shown in the figure.

For ConFlat flange connections we recommend

using Varian hardware.

1. Turbo-V

controller

To facilitate assembly and dismantling, apply Fel-

pro C-100 high temperature lubricant to the screw

threads protruding from the flange and between

the nuts and flange.

2. Vent

valve

3. Vacuum pump shut-off valve (optional)

4. System vent valve (optional)

Note that the connections can be made only with

the bolt in the lower side.

5. Vacuum

chamber

6. Ionization

gauge

Attach the units and tighten each one in turn. Re-

peat the sequential tightening until the flange faces

meet.

7. Fore-vacuum pump connecting flange

8. Oil mist eliminator

9. Fore-vacuum pump with internal one-way

valve

CAUTION

10. Fore-vacuum pump control relay

Exercise care when tightening nuts and bolts to

avoid creating dents in the envelope as this may

cause the pump rotor to lock.

11. Connection for water cooling

12. Roughing line with valve (optional)

34

87-900-874-01(B)