BDR-595D Adela

19

Never put the engine on the side. Oil might get into the exhaust or into the air

cleaner. Best engine placing is with the lower flange dwelling on two lintels which

are at least 7 cm high.

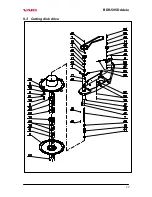

c) Dismount the upper casing and handrail (flat wrenches No. 8, 10, 13). Dismount the

column in front of the driven belt pulley (see Fig. 5.3) (spanner No. 10). Take the old V-

belt off and replace it with a new one. Original V-belt marking is

OPTIBELT

X13x1300Ld 6T6K

(Ld=calculated length). It is also possible to use an equivalent V-belt

made by other manufacturers at a size of

A13x1270 Li

(Li=internal length) or

½“ x

52“La

(La=external length). However, the belt must be made without rubber on sides!

Only such a belt model will guarantee that the blade drive start is smooth at engaging the

clutch.

Should another than the above mentioned original spare belt be used, the machine

manufacturer does not answer for correct and full functioning of the drive!

d) Put the engine back in place. Pins in the driving belt pulley, installed on the engine, must

fall into holes in the rubber element on the driven part of the clutch. Bolt the engine with

three safety nuts with flat washers. Screw the accelerator lever back onto the handlebars.

e) Put the V-belt into the groove in the belt pulley on the engine.

f) Check the operation of the tightening pulley and adjustment of guide lamination. With

the lever on the right handlebar grip fully pressed down, the pulley must ensure a

sufficient belt tension (spring on the cable being extended by about 10 mm as compared

with loose condition). Possible corrections are to be made by means of adjustment bolt

No. 2 (see Fig. 8). With the lever switched off, the pulley must be tilted away from the

longitudinal machine axis at an angle of max. 0 - 5° = with the belt convex side being

approx. 1.5 – 2.0 cm from the bottom of the tightening pulley (see Fig. 7). The cable in

the Bowden of the tension pulley must exhibit no slackness. In the case that the

adjustment bolt is completely screwed out and it is necessary to tighten the V-belt, the

spring on the cable can be hooked into the front hole on the arm of the tightening pulley

(see Fig. 7 bottom, note: this connection can be used already from the manufacturer) and

belt tension can be adjusted once again. Guide lamination on the right side of the machine

must be parallel to the belt and at a maximum distance of 1 – 2 mm from the belt convex

side.

g) Mount the column back to its original position in front of the driven belt pulley, mount

back the upper plastic casing and the handrail.

Summary of Contents for BDR-595 D Adela

Page 1: ...Brush cutter BDR 595 D Adela Instructions for use...

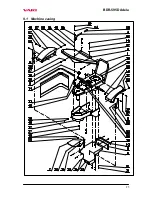

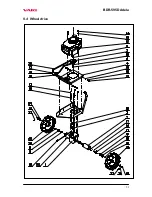

Page 7: ...BDR 595D Adela 7 LwA 2 1 8 3 4 5 6 7 11 12 9 10...

Page 25: ...BDR 595D Adela 25 9 1 Machine casing...

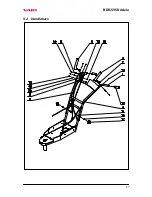

Page 27: ...BDR 595D Adela 27 9 2 Handlebars...

Page 29: ...BDR 595D Adela 29 9 3 Cutting disk drive...

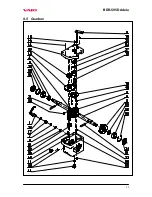

Page 31: ...BDR 595D Adela 31 9 4 Wheel drive...

Page 33: ...BDR 595D Adela 33 9 5 Gearbox...