10

104274

VENT-FREE NATURAL GAS HEATER

®

Pressure Testing Heater Gas

Connections

1.

Open equipment shutoff valve (see Fig-

ure 13).

2.

Open main gas valve located on or near

gas meter.

3.

Make sure control knob of heater is in

the OFF position.

4.

Check all joints from equipment shutoff

valve to control valve (see Figure 14).

Apply mixture of liquid soap and wa-

ter to gas joints. Bubbles forming show

a leak.

5.

Correct all leaks at once.

6.

Light heater (see Operating Heater,

pages 10 and 11). Check all other in-

ternal joints for leaks.

7.

Turn off heater (see To Turn Off Gas to

Appliance, page 11).

8.

Replace front panel.

ON

POSITION

OFF

POSITION

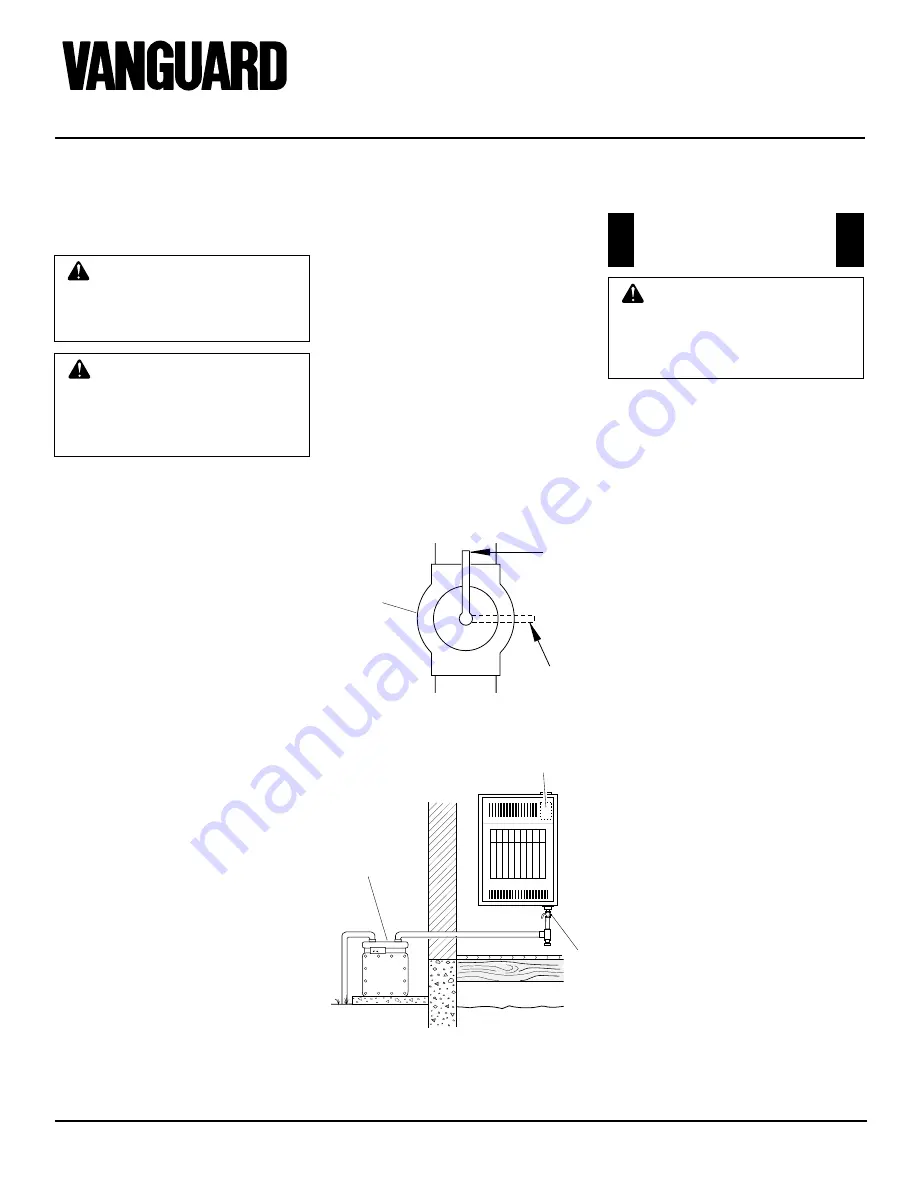

Figure 13 - Equipment Shutoff Valve

Equipment

Shutoff

Valve

Open

Closed

Control Valve

Location

Gas Meter

Equipment

Shutoff

Valve

Figure 14 - Checking Gas Joints

Pressure Testing Gas Supply

Piping System

Test Pressures In Excess Of 1/2 PSIG

(3.5 kPa)

1.

Disconnect appliance with its appliance

main gas valve (control valve) and equip-

ment shutoff valve from gas supply pip-

ing system. Pressures in excess of 1/2 psig

will damage heater regulator.

2.

Cap off open end of gas pipe where

equipment shutoff valve was connected.

3.

Pressurize supply piping system by either

using compressed air or opening main gas

valve located on or near gas meter.

4.

Check all joints of gas supply piping

system. Apply mixture of liquid soap

and water to gas joints. Bubbles form-

ing show a leak.

5.

Correct all leaks at once.

6.

Reconnect heater and equipment

shutoff valve to gas supply. Check re-

connected fittings for leaks.

Test Pressures Equal To or Less Than

1/2 PSIG (3.5 kPa)

1.

Close equipment shutoff valve (see Fig-

ure 13).

2.

Pressurize supply piping system by ei-

ther using compressed air or opening

main gas valve located on or near gas

meter.

3.

Check all joints from gas meter to equip-

ment shutoff valve (see Figure 14). Ap-

ply mixture of liquid soap and water to

gas joints. Bubbles forming show a leak.

4.

Correct all leaks at once.

CHECKING GAS

CONNECTIONS

WARNING: Test all gas pip-

ing and connections for leaks

after installing or servicing. Cor-

rect all leaks at once.

WARNING: Never use an open

flame to check for a leak. Apply a

mixture of liquid soap and water

to all joints. Bubbles forming show

a leak. Correct all leaks at once.

OPERATING

HEATER

FOR YOUR SAFETY

READ BEFORE

LIGHTING

A. This appliance has a pilot which must

be lighted by hand. When lighting the

pilot, follow these instructions exactly.

B. BEFORE LIGHTING smell all

around the appliance area for gas. Be

sure to smell next to the floor because

some gas is heavier than air and will

settle on the floor.

WHAT TO DO IF YOU SMELL

GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

• If you cannot reach your gas sup-

plier, call the fire department.

C. Use only your hand to push in or turn

the gas control knob. Never use tools.

If the knob will not push in or turn

by hand, don’t try to repair it, call a

qualified service technician or gas

supplier. Force or attempted repair

may result in a fire or explosion.

D. Do not use this appliance if any part

has been under water. Immediately

call a qualified service technician to

inspect the appliance and to replace

any part of the control system and

any gas control which has been un-

der water.

WARNING: If you do not fol-

low these instructions exactly, a

fire or explosion may result caus-

ing property damage, personal

injury or loss of life.

INSTALLATION

Continued