PRINTED IN THE U.S.A.

PAGE 3

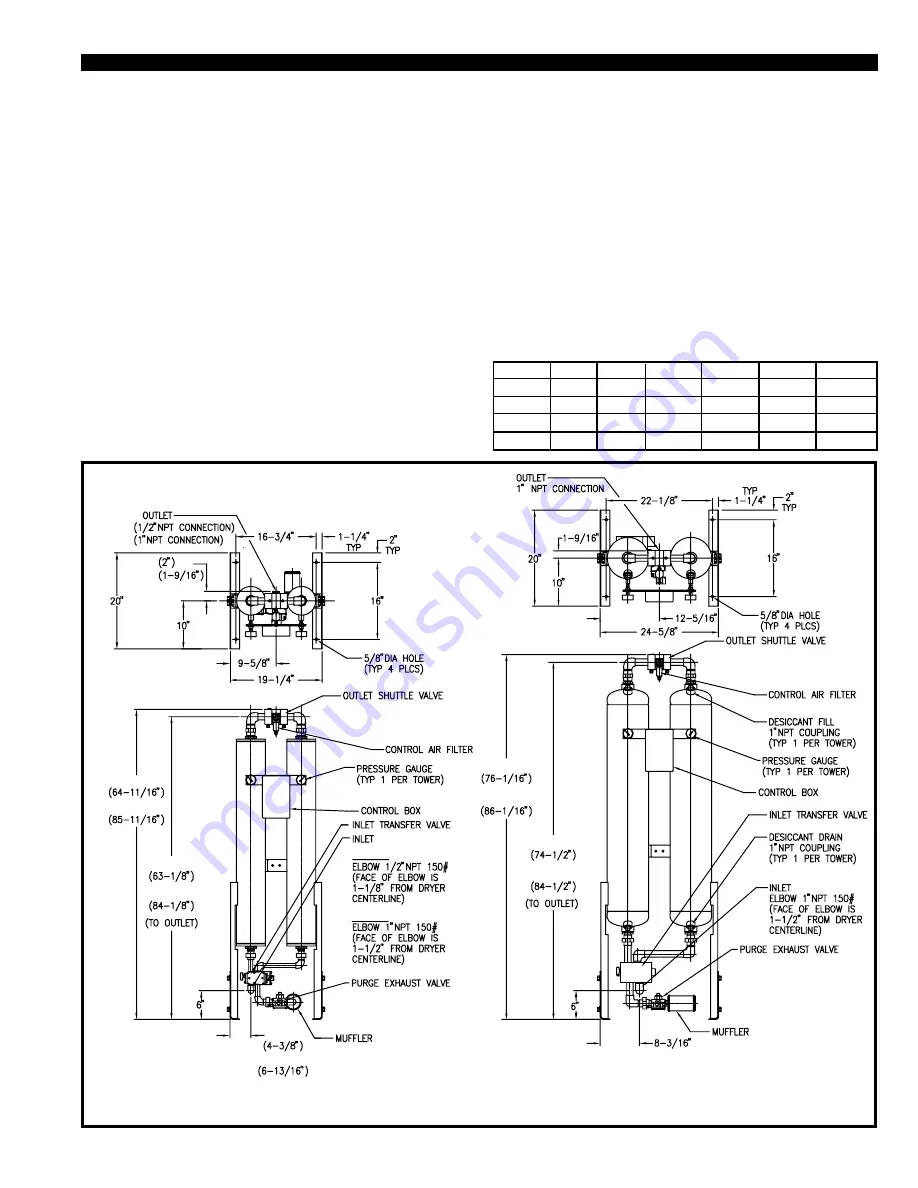

DIMENSIONS AND SPECIFICATIONS

SECTION 3

3.1 DRYER SPECIFICATIONS

WEIGHT

(with desiccant installed)

HLS-55 ....

230 lbs

HLS-80....

280 lbs

HLS-120....

385 lbs

HLS-150....

445 lbs

DIMENSIONS

See SECTION 3.2

IN/OUT CONNECTION

HLS-55....

1/2"NPT

HLS-80....

1"NPT

HLS-120....

1" NPT

HLS-150....

1"NPT

VESSELS (desiccant towers)

Design Pressure ............ 150 PSIG

Design Temperature ...... -20

O

F TO 200

O

F

PIPING

Threaded pipe fittings: ANSI B16.3

Threaded union fittings: ANSI B16.39

Pipe: Carbon Steel, Schedule 40

VALVES

Inlet ............... 4-Way, solenoid piloted

Outlet ............. Shuttle valve

Purge .............. 3-Way Valve (run as a 2-Way Valve), solenoid piloted

CONTROL AIR FILTER

Construction

...

Zinc housing

3.2 DIMENSIONS Models HLS-55 through HLS-150

HLS-55 & HLS-80

HLS-120 & HLS-150

ELECTRICAL

Nema 4 Electrical enclosure

Standard 115V ...... 115V/1PH/50-60Hz

Optional 230V: ....... 230V/1PH/50-60Hz

DESICCANT

Material .............. Activated Alumina, 1/8" (2-5 MM) Bead type

Quantity Per Tower (LBS)

HLS-55....

30.5 lbs

HLS-80....

43.5 lbs

HLS-120....

67.5 lbs

HLS-150....

82.5 lbs

OPERATING CONDITIONS

Inlet Air Pressure ............... MIN 60 PSIG ......... MAX 150 PSIG

Inlet Air Temperature ......... MIN 40

O

F ............... MAX 120

O

F

Ambient Air Temperature .. MIN 40

O

F ............... MAX 120

O

F

RATED INLET CONDITIONS

Inlet Air Pressure ................................ 100 PSIG

Inlet Air Temperature .......................... 100

O

F

Relative Humidity (saturation) ............ 100% RH

* (ROTATED TO BACK ON HLS-150)

HLS-55

HLS-80

HLS-55

HLS-80

HLS-55

HLS-80

HLS-55

HLS-80

HLS-80

HLS-55

HLS-55

HLS-80

HLS-120

HLS-150

HLS-120

HLS-150

FLOW CAPACITIES (SCFM) at various pressures (100

0

F)

60

PSIG

75

PSIG

90

PSIG

100

PSIG

125

PSIG

150

PSIG

HLS-55

36

43

50

55

61

66

HLS-80

52

63

73

80

88

96

HLS-120

78

94

110

120

132

144

HLS-150

98 117 137 150

166

180