33

Instructions for installation and servicing ecoTEC / 839592_09

5.9.2 Gas inlet working pressure

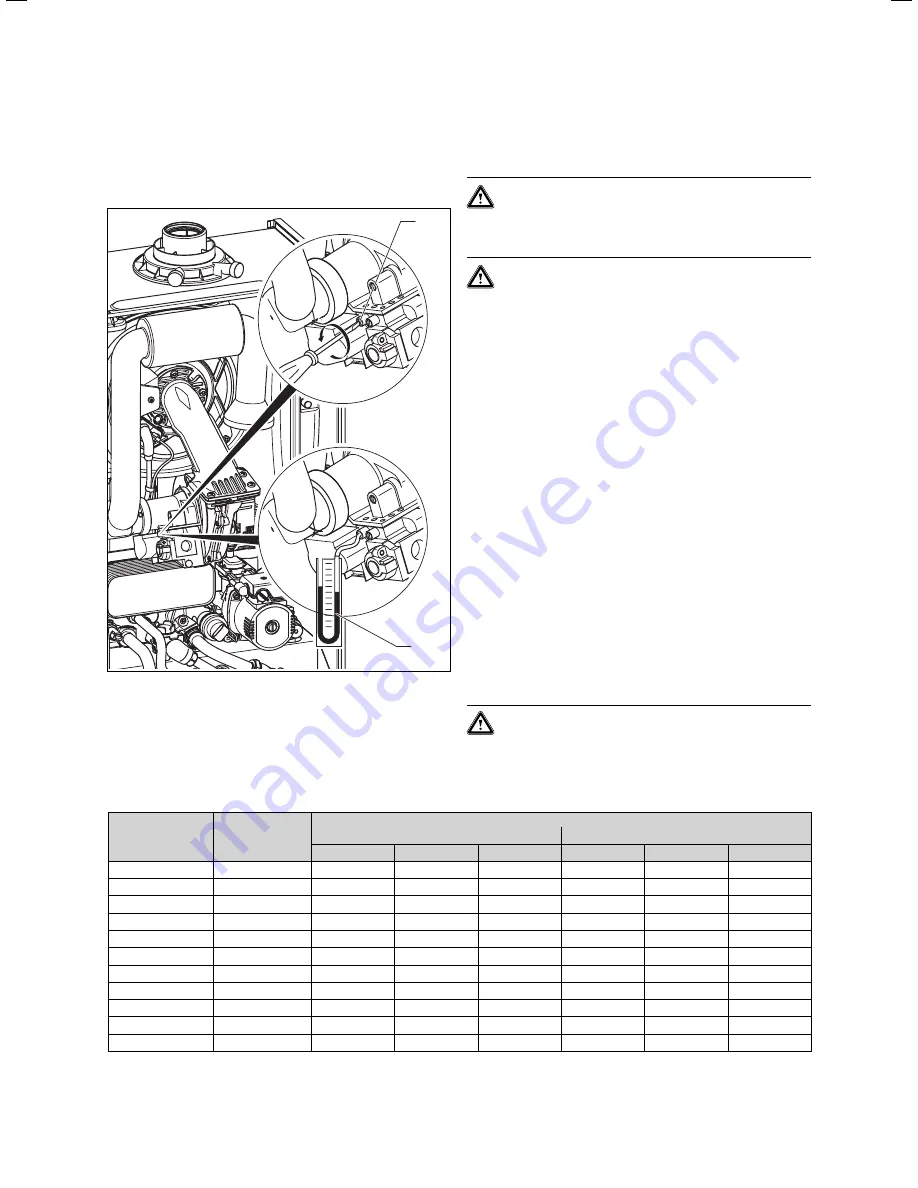

Check the inlet pressure as described below:

• Remove the front case from the boiler.

• Close the gas shutoff valve fitted to the boiler.

1

2

Fig. 5.13 Checking the gas supply pressure

• Loosen the sealing screw marked “in” (

1

) on the gas

valve assembly.

• Connect a digital or a U gauge (

2

).

• Open the gas shutoff valve fitted to the boiler.

• Put the boiler into operation (refer to the Instructions

for Use supplied with the boiler).

• Check the U gauge reading and ensure the inlet gas

pressure is between the pressures detailed below.

Caution! Natural gas:

DO NOT proceed with adjustment or attempt to

put the unit into service if the inlet working

pressure lies outside the 17–25 mbar range.

Caution! LPG:

DO NOT proceed with adjustment or attempt to

put the unit into service if the inlet working

pressure is lower than 37 mbar.

• Turn off the appliance, remove U gauge.

• Tighten the test point screw and check for leaks.

• Record appliance working gas inlet pressure (mbar) in

the Benchmark gas boiler commissioning checklist.

5.9.3 Checking the gas rate

The boiler is fitted with a fully modulating automatic gas

valve which ensures that the precise air/gas ratio is pro-

vided under all operating conditions.

The gas rate has been set during production and does

not require adjustment.

The gas rate of the boiler should be checked with the

front case fitted as follows:

• Activate full gas rate mode by simultaneously press-

ing the “

+

” and “

–

” buttons on the display system (for

ecoTEC combination boilers fully open the hot water

tap to maximum water flow rate).

• Wait at least 5 minutes, or until the boiler has reached

its operating temperature.

• With all other gas appliances turned off measure the

gas rate at the gas meter. Check that the gas rate is

as stated in Table 5.1.

Caution!

If the measured gas flow volume lies outside

the tolerance limits specified in Table 5.1, do

not operate the appliance and inform the

Vaillant Customer Service.

Commissioning Part I 5

Appliance

Maximum net

heat input in kW

Gas rate

Natural gas in m

3

/h

Propane in kg/h

nominal

+ 5%

- 10%

nominal

+ 5%

- 10%

ecoTEC plus 612

12.2

1.29

1.36

1.16

0.95

1.00

0.85

ecoTEC plus 615

15.3

1.62

1.70

1.46

1.19

1.25

1.07

ecoTEC plus 618

18.4

1.95

2.04

1.75

1.43

1.50

1.29

ecoTEC plus 624

24.5

2.59

2.72

2.33

1.90

2.00

1.71

ecoTEC plus 630

30.6

3.24

3.40

2.91

2.38

2.50

2.14

ecoTEC plus 637

37.8

4.00

4.20

3.60

2.94

3.08

2.64

ecoTEC plus 824

23.5

2.49

2.61

2.24

1.83

1.92

1.64

ecoTEC plus 831

31.6

3.34

3.51

3.01

2.45

2.58

2.21

ecoTEC plus 837

37.8

4.00

4.20

3.60

2.94

3.08

2.64

ecoTEC pro 24

23.5

2.49

2.61

2.24

1.83

1.92

1.64

ecoTEC pro 28

28.6

3.03

3.18

2.72

2.22

2.33

2.00

Table 5.1 Gas rates

Summary of Contents for ecoTEC pro 24

Page 51: ...51 Instructions for installation and servicing ecoTEC 839592_09 Appendix Appendix...

Page 52: ...Benchmark gas boiler commissioning checklist...

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ...839592_09 GB 05 2008...