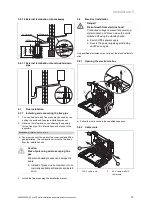

9 Handing the product over to the end user

20

Installation and maintenance instructions ecoFIT pure 0020230535_05

8.1.1

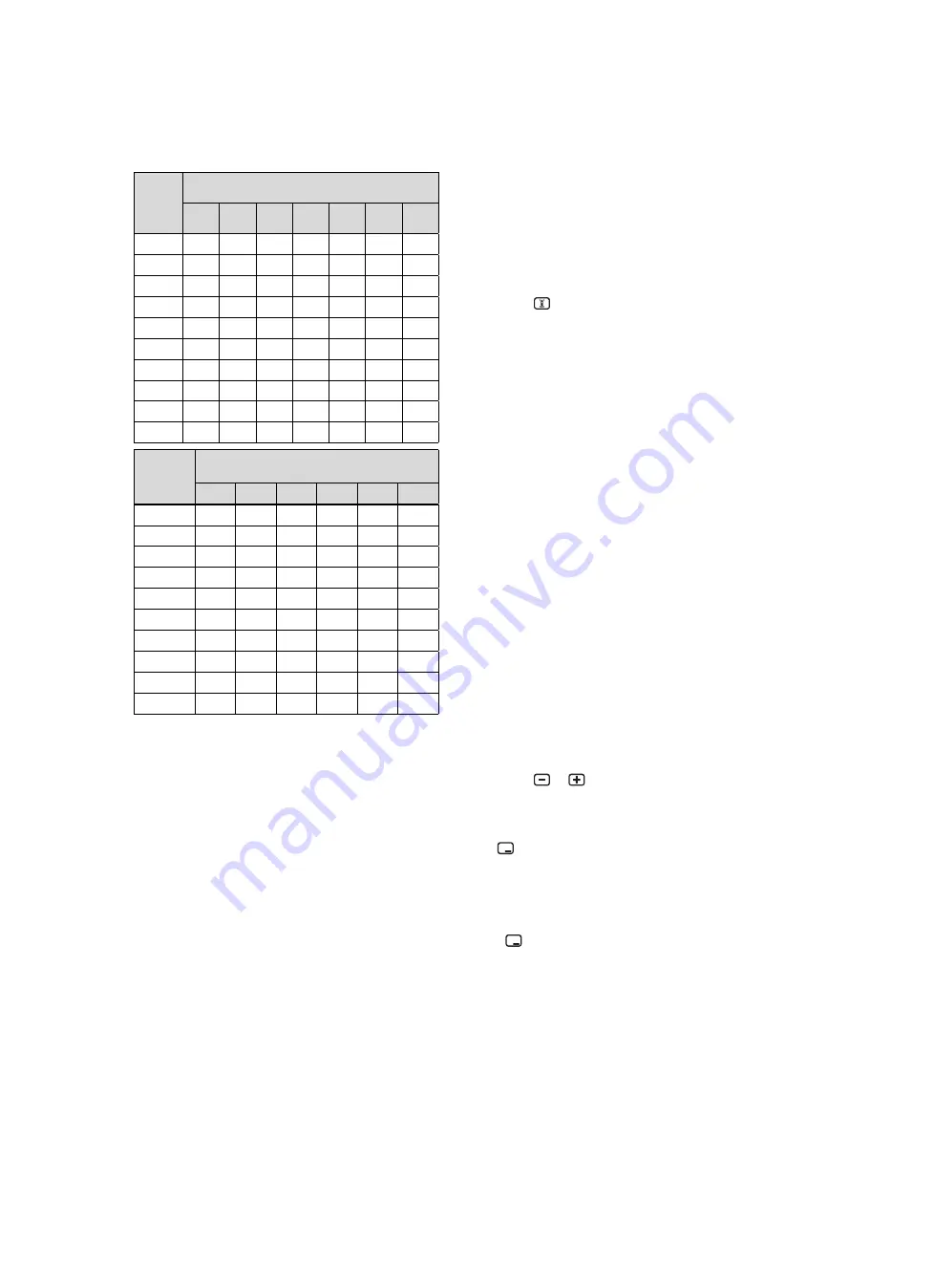

Setting the burner anti-cycling time

▶

Set the burner anti-cycling time via the diagnostics code.

Overview of diagnostics codes (

→

Page 27)

T

Flow

(tar-

get)

[°C]

Set maximum burner anti-cycling time [min]

1

5

10

15

20

25

30

30

2.0

4.0

8.5

12.5

16.5

20.5

25.0

35

2.0

4.0

7.5

11.0

15.0

18.5

22.0

40

2.0

3.5

6.5

10.0

13.0

16.5

19.5

45

2.0

3.0

6.0

8.5

11.5

14.0

17.0

50

2.0

3.0

5.0

7.5

9.5

12.0

14.0

55

2.0

2.5

4.5

6.0

8.0

10.0

11.5

60

2.0

2.0

3.5

5.0

6.0

7.5

9.0

65

2.0

1.5

2.5

3.5

4.5

5.5

6.5

70

2.0

1.5

2.0

2.5

2.5

3.0

3.5

75

2.0

1.0

1.0

1.0

1.0

1.0

1.0

T

Flow

(target)

[°C]

Set maximum burner anti-cycling time

[min]

35

40

45

50

55

60

30

29.0

33.0

37.0

41.0

45.0

49.5

35

25.5

29.5

33.0

36.5

40.5

44.0

40

22.5

26.0

29.0

32.0

35.5

38.5

45

19.5

22.5

25.0

27.5

30.5

33.0

50

16.5

18.5

21.0

23.5

25.5

28.0

55

13.5

15.0

17.0

19.0

20.5

22.5

60

10.5

11.5

13.0

14.5

15.5

17.0

65

7.0

8.0

9.0

10.0

11.0

11.5

70

4.0

4.5

5.0

5.5

6.0

6.5

75

1.0

1.0

1.0

1.0

1.0

1.0

8.1.2

Resetting the remaining burner anti-cycling

time

▶

Press the reset button.

9

Handing the product over to the end

user

▶

When you have finished the installation, attach the sticker

supplied (in the end user's language) to the product

cover.

▶

Explain to the end user how the safety devices work and

where they are located.

▶

Inform the end user how to handle the product.

▶

In particular, draw attention to the safety information

which the end user must follow.

▶

Inform the end user that they must have the product

maintained in accordance with the specified intervals.

▶

Instruct the end user about measures taken for routing

the combustion air supply and flue system.

10 Troubleshooting

10.1

Eliminating faults

▶

If fault messages (

F.xx

) appear, eliminate the fault after

referring to the table in the appendix or using the check

programmes. (

→

Page 16)

Overview of fault codes (

→

Page 31)

If several faults occur at the same time, the display shows

the corresponding fault messages for two seconds each in

alternation.

▶

Press

(max. three times) to restart the product.

▶

If you are unable to eliminate the fault and the fault re-

curs despite reset attempts, contact customer service.

10.2

Procuring spare parts

The original components of the product were also certified

by the manufacturer as part of the declaration of conformity.

If you use other, non-certified or unauthorised parts during

maintenance or repair work, this may void the conformity of

the product and it will therefore no longer comply with the

applicable standards.

We strongly recommend that you use original spare parts

from the manufacturer as this guarantees fault-free and safe

operation of the product. To receive information about the

available original spare parts, contact the contact address

provided on the reverse of these instructions.

▶

If you require spare parts for maintenance or repair

work, use only the spare parts that are permitted for the

product.

10.3

Calling up and clearing the fault memory

The last 10 fault messages are stored in the fault memory.

▶

Call up the installer level. (

→

Page 15)

▶

Navigate to the

fault codes

.

◁

The number of faults that have occurred is shown in

the display and the faults that are currently called up

are displayed with their fault numbers

F.xx

.

▶

Press

or

to call up individual fault messages.

▶

To delete the entire fault list, navigate to diagnostics code

D.094

in the installer level.

▶

Set the diagnostics code to

1

, and confirm by pressing

.

10.4

Resetting parameters to factory settings

1.

Navigate to diagnostics code

D.096

in the installer level.

2.

Set the diagnostics code to 1, and confirm by pressing

.