8

BOILER

WATER INLET

ALTERNATE

CIRCULATOR

LOCATION

TO SYSTEM

FROM SYSTEM

CIRCULATOR

SHUT-OFF

VALVE

PRESSURE

REDUCER VALVE

CHECK VALVE

BALL VALVE

3 WAY MIXING

VALVE

AIR SEPARATOR

HOSE BIB

EXPANSION

TANK

7.

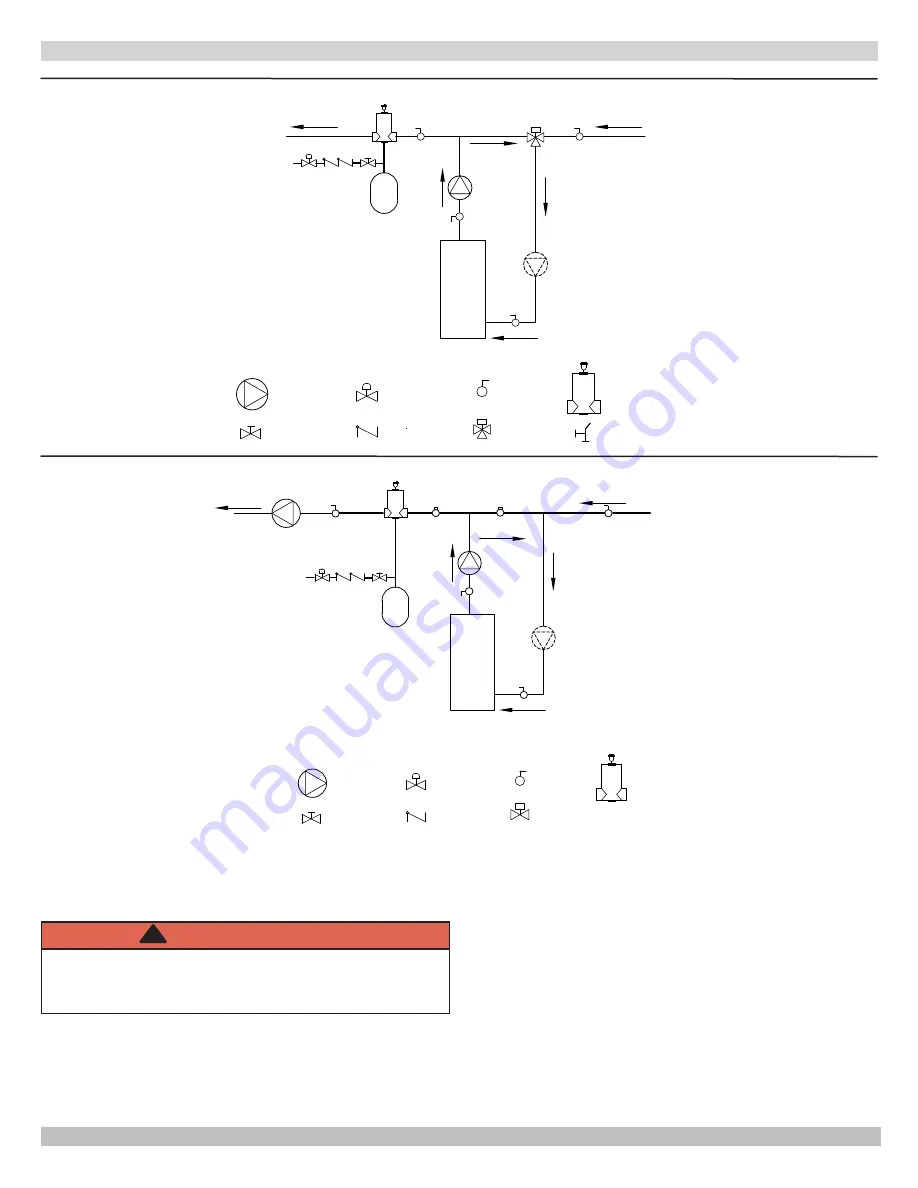

Installation using circulators and zone valves are

shown in Figures 8-11. For further piping information

refer to I=B=R Installation and Piping Guide.

WARNING

Burn and scald hazard. Safety relief valve could

discharge steam or hot water during operation.

Install discharge piping per these instructions.

!

8.

Install discharge piping from safety relief valve.

Use ¾" or larger pipe.

•

Use pipe suitable for temperatures of 375°F (191°C)

•

or greater.

Individual boiler discharge piping shall be independent

•

of other discharge piping.

Size and arrange discharge piping to avoid reducing

•

safety relief valve relieving capacity below minimum

relief valve capacity stated on rating plate.

Run pipe as short and straight as possible to location

•

protecting user from scalding and properly drain

piping.

Install union, if used, close to safety relief valve outlet.

•

Install elbow(s), if used, close to safety relief valve

•

outlet and downstream of union (if used).

Terminate pipe with plain end (not threaded).

•

connectIng supply and return pIpIng

BOILER

ALTERNATE

CIRCULATOR

LOCATION

TO SYSTEM

FROM SYSTEM

V2

V1

CIRCULATOR

SHUT-OFF

VALVE

PRESSURE

REDUCER VALVE

CHECK VALVE

BALL VALVE

AIR SEPARATOR

ZONE VALVE

EXPANSION

TANK

WATER INLET

SYSTEM

CIRCULATOR

Figure 6 - Bypass Piping Automatic Mixing Valve

Figure 7 - Bypass Piping - Fixed Low Temp Only Automatic Mixing Valve