17

VIII - TROUBLESHOOTING

SOFT LOCKOUT

(Display flashes “9” and then “b” in first position; last two digits on steady (code))

Code

Reason For Soft Lockout

Corrective Actions

(pressing RESET should restart boiler immediately):

WARNING:

Electrical shock hazard. Turn off power to boiler when working with wiring or replacing any boiler component.

24

High Limit Operation:

Return temp.

is higher than supply temp.

1

Verify boiler and system are full of water.

•

Make sure system does not have trapped air.

•

Inspect and verify system piping and components.

•

Make sure water flow is not reversed or pipes crossed.

•

2

Use contact thermometer to check return water temp. Compare to temp. shown with

display in “INFO” mode (

“2”

in first digit). Replace return temp. sensor if results are

not close. Replace control module if sensor replacement doesn’t solve problem.

25

High limit operation:

outlet water

temp. increased too quickly.

Non-adjustable default setting

9.8°F/sec

1

This usually indicates flow rate too low. Check system for:

Verify boiler and system are full of water.

•

Make sure system does not have trapped air.

•

Inspect and verify system piping and components.

•

Verify piping agrees with boiler manual recommendations.

•

2

Verify operation of boiler circulator:

Check voltage at circulator junction box to ensure 120 vac when boiler oper

-

•

ates. if no voltage, check wiring and wiring connections.

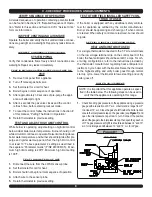

High voltage terminal strip terminals 5 and 6 should show 120 vac for space

•

heating; terminals 3 and 4 should show 120 vac for DHW. Replace circulator if

powered but not operating.

Replace line voltage wire harness if necessary. Replace control module if wire

•

replacement doesn’t resolve.

26

aquastat contacts open

or

LWCO contacts open

or

3.5” Switch open

1

Verify proper setting of control.

•

Water temp too high, wait for temperature to drop below 180 degrees.

•

2

Check water level in boiler, fill if low.

•

Press LWCO reset switch on display panel

•

If problem still exists, check LWCO probe and board according to manufacturer’s

•

instructions. replace if necessary.

3

Check pressure switch for proper operation. Replace if moisture has entered switch.

Check venting for blockage. Clear if present.

29

Blower turning when it should be off.

1

Check boiler wiring against wiring diagram. Replace line voltage and low voltage

wiring harnesses if necessary. Replace control module if wire replacement doesn’t

resolve.

30

High limit operation:

Temp. rise

across boiler too high.

1

This usually indicates flow rate too low. Check system for:

Verify boiler and system are full of water.

•

Inspect and verify system piping and components.

•

Verify piping agrees with boiler manual recommendations.

•

Make sure system pressure drop is not too high.

•

2

Verify operation of boiler circulator.

Check voltage at circulator junction box to ensure 120 vac when boiler

•

operates. if no voltage, check wiring and wiring connections.

High voltage terminal strip terminals 5 and 6 should show 120 vac for space

•

heating; terminals 3 and 4 should show 120 vac for DHW. Replace circulator

if powered but not operating.

Replace line voltage wire harness if necessary. Replace control module if wire

•

replacement doesn’t resolve.

61

Pressure switch contacts closed.

1

Check pressure switches for proper operation. Replace pressure switch if moisture

has entered switch.

65

Blower not operating when turned

on.

1

Turn off power to boiler. Remove line voltage connector at blower. Restart boiler

and check voltage across blower plug terminals. If 120 vac is

NOT

present, inspect

wiring and tightness of connections. replace line voltage wire harness if necessary.

Replace control module if wire harness replacement doesn’t resolve.

2

If 120 vac is present on blower wire harness, replace harness and retry. If problem

persists, replace blower motor.