2

June 2011

06-237172-001 Rev AA

CONTROL CROSS REFERENCE

INSTALLATION GUIDELINES

MOUNTING AND WIRING

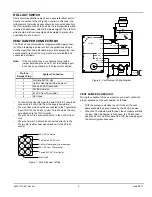

The 35-63J is not position sensitive and can be mounted verti-

cally or horizontally. The case may be mounted on any surface

with #6 sheet metal screws.

HIGH VOLTAGE TERMINAL CONNECTION

The Fenwal 35-63J uses a Rajah (spark plug) type HV connec-

tion which is common to most controls. If the control being

replaced does not utilize a Rajah connection, the HV spark

cable will need to be replaced or re-terminated using a Rajah

style female mating connector.

Manufacturer/ Model Number

Johnson Controls

Fenwal Replacement

G770KGA-1,3

35-63J101-011

G770KHA-2

35-63J101-011

G770LGA-1,2

35-63J103-013

G770LGC-1,2,3,4,10

35-63J103-013

G770LHA-1,2

35-63J103-013

G770LHC-1

35-63J103-013

G770MGA-1,2,5

35-63J101-015

G770MHA-2

35-63J101-015

G770MGC-1,3

35-63J101-415

G770MHC-1

35-63J101-415

G770NGA-1

35-63J103-017

G770NGC-4,5,6,7

35-63J103-017

G770NHA-1

35-63J103-017

G770NHC-1

35-63J103-017

G770RHA-2

35-63J103-017

G77RJA-1

35-63J103-017

G775RGA-1,2,3

35-63J103-017

G775RHA-1,2

35-63J103-017

G775RJD-1,2,13,14,15

35-63J103-117

G776RGD-11,14

35-63J303-117

G775LHA-1

(remote flame sense)

35-63J103-013

G779LHA-1 “Universal”

(set-up for Remote flame sense)

35-63J103-013

G779LHA-1 “Universal”

(set-up for Local flame sense)

35-63J102-013

CAUTION

Label all wires prior to disconnection when

servicing or replacing controls. Wiring errors

can cause improper and dangerous

operation. A functional checkout of a

replacement control should always be

performed.

WARNING

The control must be mounted and located in

a manner which protects components from

exposure to water (dripping, condensate,

spraying, rain). Any control that has been

exposed to water must be replaced.

WARNING

All wiring must be done in accordance with

both local and national electrical code.

Wiring must be at least #18 AWG rated for

105°C or higher.

WARNING

The 35-63J uses voltages of shock hazard

potential. Wiring and initial operation must

be done by qualified service technician.

WARNING

Operation outside specifications could result

in failure of the Fenwal product and other

equipment with injury to people and

property.

Wiring Terminal Names

JCI G77x

Fenwal

35-63J

Description

2 THS

THS

Thermostat Input

1 PV

PV

Pilot Valve Power

3 MV

MV

Main Valve Power

Ground Plate

_GND

Valve Ground

Ground Plate

GND_

Valve Ground

Ground Plate

GND

System Ground

BLIND

BLIND

No Connection

4 SENSE

SENSE

Remote Flame Sensor