95-8401

21

2.1

existing filter from the housing, then replace it with a

new filter. Use care not to over tighten.

NOTE

A dirty hydrophobic filter can adversely affect the

response of the sensor by blocking the flow of gas

to the sensing element. If the detector cannot be

calibrated or responds slowly to the calibration gas,

check the condition of the hydrophobic filter before

replacing the sensing element assembly. The

hydrophobic filter should be clean and squarely

seated in the housing.

SENSING ELEMENT REPLACEMENT

The area must be de-classified or power to the sensor

must be removed prior to replacing the sensing

element in a hazardous area.

To replace the sensing element:

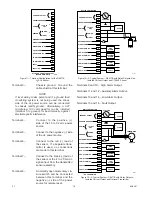

1. If the controller will remain powered during sensor

replacement, enter the sensor replacement mode

by pressing and holding the RESET button for

approximately 9 seconds until the digital display

begins fl ashing and the CAL LED is illuminated.

Release the RESET button.

2. Press the SET button. The FAULT LED also

comes on. The controller is now in the Sensor

Replacement mode.

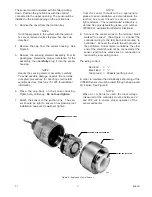

3. Remove the cap from the sensor housing. See

Figure 6. (There is no need to remove the sensor

housing from the junction box.)

4. Remove and discard the old sensing element

assembly. Check for corrosion or contamination

on the terminals inside the sensor enclosure, and

clean if necessary.

5. Determine proper orientation for the new assem-

bly, then

carefully

plug it in.

NOTE

Handle the sensing element assembly carefully.

To avoid possible damage, observe the normally

accepted procedures for handling electrostatic

sensitive devices. See form 75-1005 for additional

information.

6. Place the cap back on the sensor housing.

Tighten only until snug.

Do not over tighten.

7. Re-apply power. Allow time for the unit to warm

up and stabilize (approximately one hour for best

results), then calibrate.

NOTE

If power was removed from the controller during

the sensing element replacement procedure, the

controller will automatically return to the Normal

mode when power is restored (after a time delay).

To prevent the possibility of alarms, allow the

system to warm up in the sensor replacement

mode. The sensor replacement mode can be

entered during the power-up time delay by holding

the RESET button for 7 seconds.

If performing a transmitter calibration, leaving the

controller in the Sensor Replacement mode until after

the calibration is complete will prevent any alarms.

If using the controller calibration method, exit the

Sensor Replacement mode and calibrate.

Press RESET to exit the Sensor Replacement mode.

The controller will enter the Normal mode after a time

delay.

An adequate supply of spare sensing element

assemblies should be kept on hand for field

replacement. For maximum protection against

contamination and deterioration, they should not

be removed from the original protective packaging

until the time of installation. To ensure maximum

storage life, sensing elements should be stored at a

temperature between 32° and 68°F (0 to 20°C) and a

relative humidity between 15 and 90 percent.

NOTE

The sensing element assembly contains an acid

that occasionally can leak. If leakage should

occur, gloves should be worn when handling

the assembly. If acid comes in contact with the

skin, wash the affected area thoroughly with soap

and water. Dispose of all old sensing elements

properly, even if leakage is not detected. Never

attempt to open the sensing element assembly.

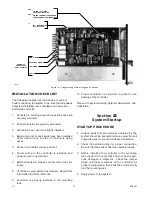

Controller Calibration

If transmitters are being used and the system is

being calibrated using the “Controller Calibration”

method, the most accurate calibration for a new

sensor will be achieved if a transmitter calibration

is performed first (as soon as the sensor output has

stabilized). Then perform the “Controller Calibration”

procedure described in the “Calibration” section of

this manual (24 hours later for maximum accuracy).

The controller calibration procedure can then be used

for all subsequent calibrations.

Refer to the “Calibration” section of this manual for the

recommended calibration schedule for a new sensor.

A Recommended Test Form is supplied at the back of

this manual for recording maintenance performed on