18

Otherwise, the motor can be easily moved by

placing a prying tool beneath it. A commer-

cially available spreader or other belt tension-

ing device can also be helpful.

Follow the procedures outlined below to cor-

rectly set and measure tension.

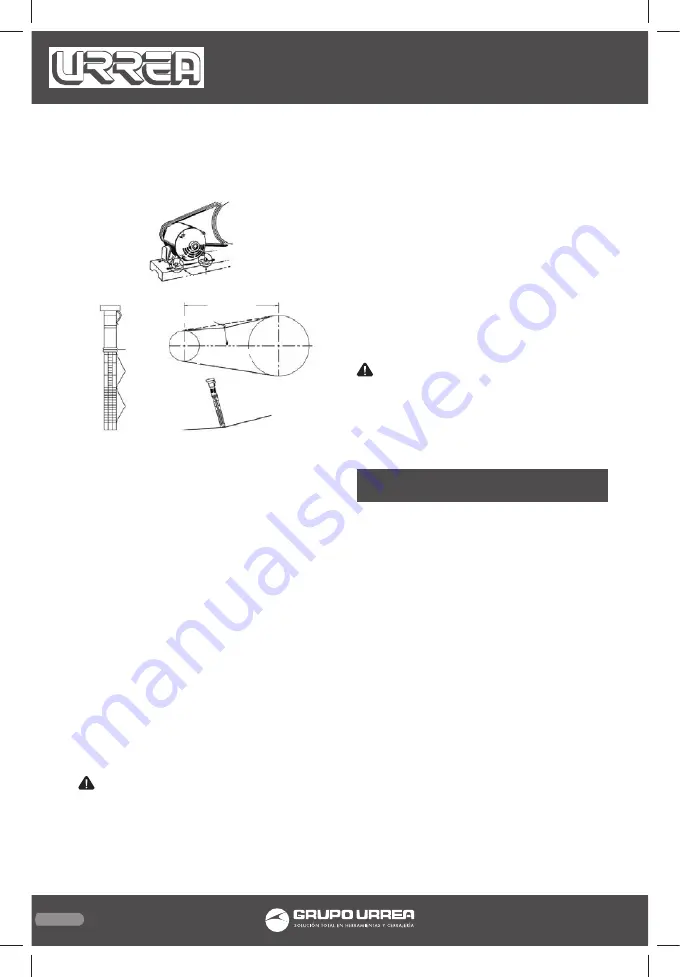

1. Measure the span length (t) of the drive.

2. Determine the amount of deflection (in

inches) required to measure deflection force

(in pounds) by multiplying the span length (t)

by 1/64. For example, a 32” span length multi-

plied by 1/64 equals 1/2” of deflection required

to measure deflection force.

3. Lay a straight edge across the top outer sur-

face of the belt drive from pulley to sheave.

4. At the center of the span, perpendicular to

the belt, apply pressure to the outer surface of

the belt with a tension gauge. Force the belt

to the predetermined deflection calculated in

step 2. Compare the reading on the tension

gauge to the BELT TENSION TABLE in the DIA-

GRAMS & TABLES section.

Ensure the pulley and sheave are properly

aligned and the motor anchor screws are ad-

equately retightened prior to restarting the

compressor.

CAUTION: Improper pulley/sheave align-

ment and belt tension can result in motor over-

load, excessive vibration, and premature belt

and/or bearing failure.

TANK INSPECTION

The life of an air receiver tank is dependent

upon several factors including, but not limited

to, operating conditions, ambient environ-

ments, and the level of maintenance. The exact

effect of these factors on tank life is difficult

to predict; therefore, URREA recommends that

you schedule a certified tank inspection within

the first five years of compressor service. To ar-

range a tank inspection, contact your closest

service center.

If the tank has not been inspected within the

first 10 years of compressor service, the re-

ceiver must be taken out of service until it has

passed inspection. Tanks that fail to meet re-

quirements must be replaced.

WARNING: Failure to replace a rusted air

receiver tank could result in air receiver tank

rupture or explosion, which could cause sub-

stantial property damage, severe personal

injury, or death. Never modify or repair tank.

Obtain replacement from service center.

TROUBLE SHOOTING:

AIR COMPRESSOR

POWER ON, BUT MOTOR DID NOT RUN,

AND FUSE BREAK OR SWITCH OFF AT

SAME TIME

Input power cable is too long ,or too small. Use

the standard power cable.

Input power voltage is too low. Check the

power voltage.

Outdoor temperature is too low. Use the

heater or change the oil.

The fuse or the over load protector is too

small. Inspect the fuse or over load protector.

Motor problems. Change motor.

The short cut in the power circuit. Inspect the

short cut protectors.

The problem of air switch. Change the air

switch.

THE AIR COMPRESSOR DID NOT WORK IF

THE POWER ON

Power cable is not connect firmly. Connect the

power cable with machines.

Air switch is in “off’ condition. Put the air

switch in “on”.

Air pump do not have the oil[ grease. Fill in the

oil in the middle of oil glass.

ANCHOR BOLTS

BELT SPAN (t)

DIRECTION OF

FORCE APPLIED

DEFLECTION

O-RINGS

DEFLECTION

FORCE SCALE

DEFLECTION

DISTANCE

SCALE

COMP8115 manual.indd 18

30/11/15 5:13 p.m.