5

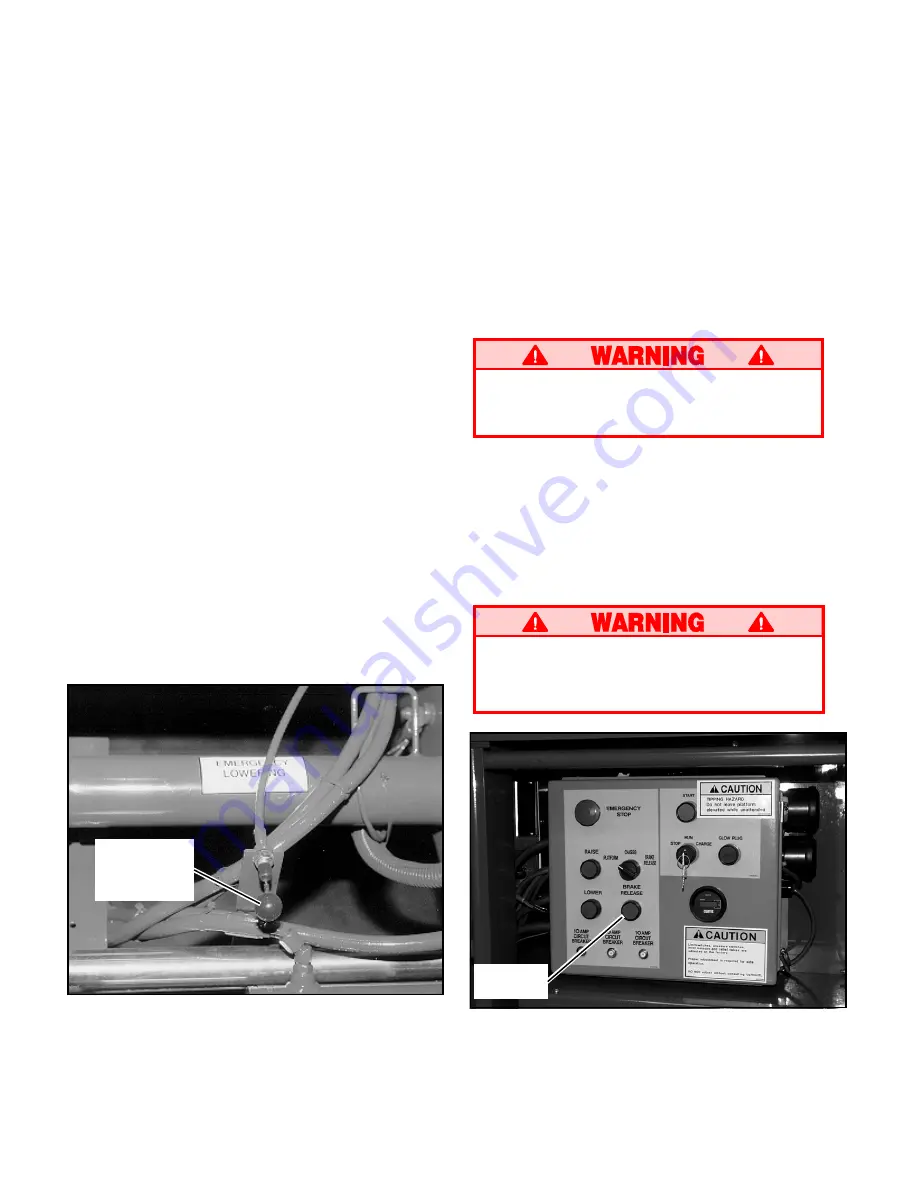

Figure 4: Emergency Lowering Knob

After Use Each Day

1. Ensure that the platform is fully lowered.

2. Park the machine on level ground, preferably

under cover, secure against vandals, children

or unauthorized operation.

3. Turn the key switch to

OFF

and remove the

key to prevent unauthorized operation.

Parking Brake Release (Figure 5)

Perform the following only when the machine will

not operate under its own power and it is neces-

sary to move the machine or when winching onto

a trailer to transport.

Never release brakes if machine is on a

slope. Hook machine to towing vehicle

before releasing brakes.

1. Turn Platform/Chassis/Brake Release switch

to Brake Release position. Alarm will sound.

2. Momentarily push brake Release button.

3. The machine will now roll when pushed or

pulled.

4. For normal operation, turn Platform/Chassis/

Brake Release switch to Platform position.

Never operate work platform with the

parking brakes released. Serious injury or

damage could result.

Travel with Work Platform Elevated

Travel with platform elevated

ONLY

on firm and

level surfaces.

Note: The work platform will travel at reduced

speed when in the elevated position, and only

when the front axle is parallel with the rear axle.

1. Check that the route is clear of persons, ob-

structions, holes and drop-offs, surface is level

and capable of supporting the wheel loads.

2. Check clearances above, below and to the sides

of platform.

3. Position the drive/lift switch to the

DRIVE

position.

4. Push the control lever to

FORWARD

or

RE-

VERSE

for the desired direction of travel.

If the machine quits driving and the tilt alarm

sounds, immediately lower the platform and

move the machine to a level location before re-

elevating the platform.

Emergency Lowering

The emergency lowering knob is located at the

front of the machine at the base of the scissor

assembly (Figure 4).

1. Open the emergency lowering valve by pulling

on the knob and holding it.

2. Once the platform is fully lowered, release the

knob to close the valve.

Emergency

Lowering

Knob

Brake

Release

Figure 5: Parking Brake Release Button

All manuals and user guides at all-guides.com