Page 3-7

Maintenance

3.5 - Switch Adjustments

TL50 Service & Parts

B

OOM

R

EST

L

IMIT

S

WITCH

Function: This limit switch is activated when the booms are fully stowed and the lower boom is

sitting in the boom rest. The outriggers can only be operated when this switch is activated. The

limit switch lever is actuated by the lower boom when is sits into the boom rest. When the boom

leaves the boom rest the Normally Open contacts of the limit switch open and power is cut to the

outrigger function switches.

Location: The switch is located on the chassis assembly.

Adjustment: The switch should be activated when the boom sits in the boom rest. The lever is

non-adjustable,but should be checked for freedom of movement and kept clean from dirt and

other contaminants that might affect its free movement.

O

UTRIGGER

L

IMIT

S

WITCHES

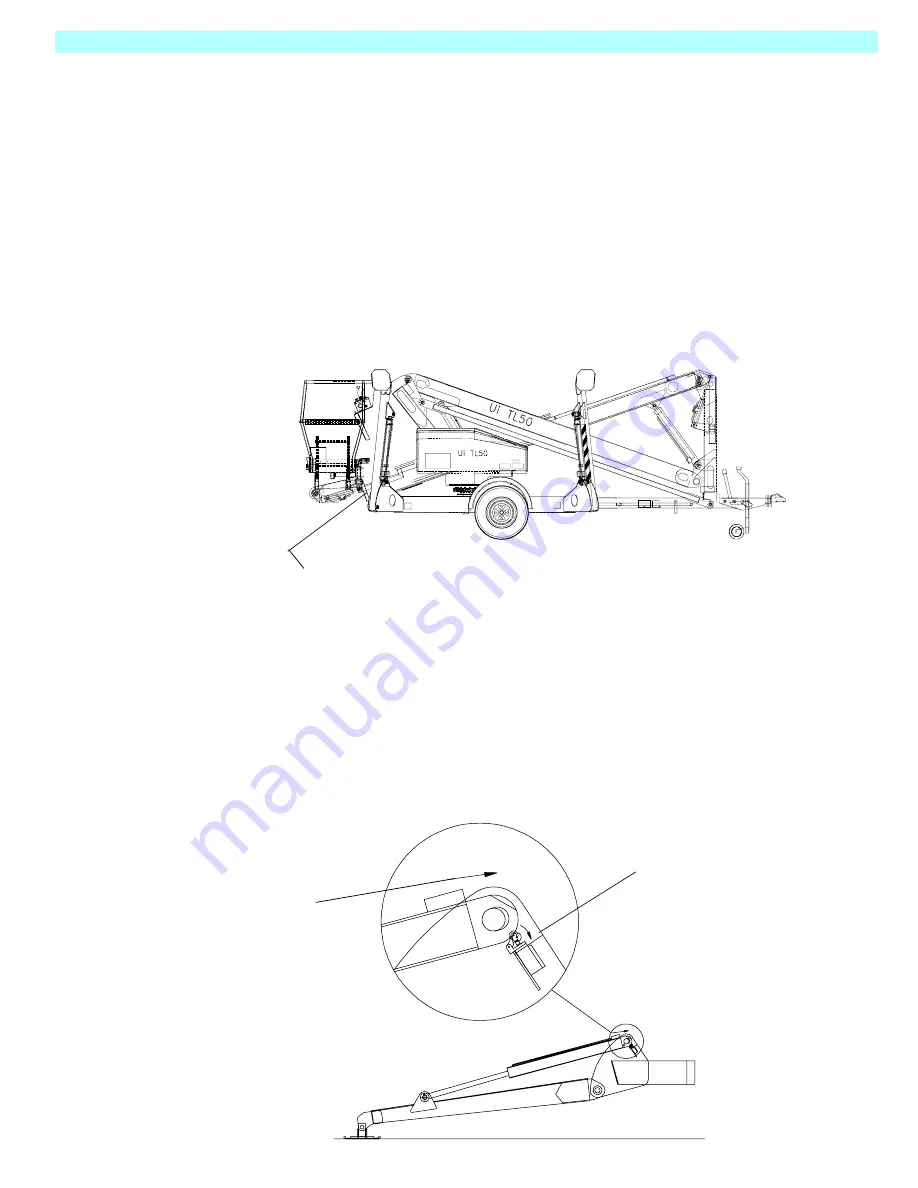

Function: These four limit switches are wired in series.

When the four outriggers are deployed these switches are activated and allow the booms func-

tions to be operated.

Location: Between the outrigger pivot plates.

Adjustment: The lever is non-adjustable and should be depressed by the outrigger cylinder head

when the outriggers are deployed. It should be checked for freedom of movement and kept clean

from dirt or other contaminants.

Function: This limit switch is activated when the booms are fully stowed and the lower boom is sitting in the boom rest. The outriggers can only be operated when this switch is activated. The limit switch lever (or ball :- pre-serial number 1008) is actuated by the lower boom when is sits into the boom rest. When the boom leaves the boom rest the Normally Open contacts of the limit switch open and power is cut to the outrigger function switches.

Location: The switch is located on the chassis assembly.

Adjustment:

The switch should be activated when the boom sits in the boom rest. The lever is non-adjustable,but should be checked for freedom of movement and kept clean from dirt and other contaminants that might affect its free movement.

Switch Location (rear left outrigger mounting)

Ensure lever is free

to rotate as shown

Outrigger cylinder moves

in this direction when the

outrigger touches

the ground

Summary of Contents for 503502-000

Page 1: ...ERVICE PARTS MANUAL POWERED ACCESS WORK PLATFORM TL50...

Page 21: ...Page 16 TL50 Service Parts Specifications Notes...

Page 51: ...Page 3 30 Maintenance 3 19 Torque Specifications TL50 Service Parts NOTES...

Page 59: ...Page 5 2 Schematics 5 1 Introduction TL50 Service Parts...

Page 60: ...Page 5 3 Schematics 5 1 Introduction TL50 Service Parts...

Page 61: ...Page 5 4 Schematics 5 1 Introduction TL50 Service Parts...

Page 62: ...Page 5 5 Schematics 5 1 Introduction TL50 Service Parts...

Page 63: ...Page 5 6 Schematics 5 1 Introduction TL50 Service Parts Notes...

Page 66: ...Page 6 3 Illustrated Parts Breakdown General Assembly TL50 Service Parts 1 1 2 3 4 5 6 7...

Page 70: ...Page 6 7 Illustrated Parts Breakdown Booms Posts Assembly TL50 Service Parts 44 45...

Page 72: ...Page 6 9 Illustrated Parts Breakdown Platform Assembly Standard TL50 Service Parts...

Page 74: ...Page 6 11 Illustrated Parts Breakdown Platform Assembly Rotator TL50 Service Parts...

Page 88: ...Page 6 25 Illustrated Parts Breakdown Hydraulic Tank Assembly TL50 Service Parts...

Page 90: ...Page 6 27 Illustrated Parts Breakdown Electrical Assembly TL50 Service Parts...

Page 92: ...Page 6 29 Illustrated Parts Breakdown Hydraulic Assembly TL50 Service Parts...

Page 94: ...Page 6 31 Illustrated Parts Breakdown Decal Assembly TL50 Service Parts...

Page 95: ...Page 6 32 Illustrated Parts Breakdown Decal Assembly TL50 Service Parts...

Page 96: ...Technician s Print TL50 W ork Platform Electrical Schematic...

Page 97: ...Technician s Print TL50 W ork Platform Harness Schematic...

Page 98: ......