(7)

♦

♦

♦

♦

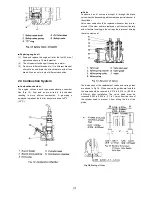

Replacing engine oil

(1) Drain and replace the engine oil after the first 35 hrs of

operation and every 75 hrs thereafter.

(2) The oil is easier to change if the engine is warm.

(3) Do not mix different brands of oil. If a different brand of

oil must be used, drain the oil and replace with all one

brand. Also, do not mix oils of different viscosities.

2.3 Combustion System

♦

♦

♦

♦

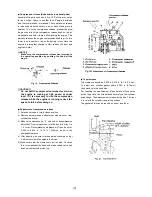

Combustion chamber

The engine utilizes a swirl type pre-combustion chamber.

See

(Fig. 13). Fuel and air are mixed in this chamber

resulting in more efficient combustion. A glow-plug s

employed to preheat the fuel for easy starts down to 5

0

F

(-15

0

C).

♦

♦

♦

♦

Valve

Combustion air, of course is brought in through the intake

valve when the descending piston creates a partial vacuum in

the cylinder.

Valve stem seals should be replaced whenever they are re-

moved. If the stem seal are replaced, coat the stem liberally

with oil before inserting in the valve guide to prevent burning

the valve stem seal.

The dimensions of the replacement valves and valve guides

are shown in Fig 16. When new valve guides are installed,

the bores should be reamed to 0.316 to 0.315 in. (8.030 to

8.015mm) after installation. The valve head must be

recessed 0.043 to 0.055 in. (1.1 to 1.4mm) from the face of

the cylinder head to prevent it from hitting the top of the

piston.

Summary of Contents for Universal diesel 5416

Page 21: ...19...