1-6-4

T6627EA

5. V. Size Adjustment

Purpose: To obtain correct vertical height of screen

image.

Symptom of Misadjustment: If V. Size is incorrect,

vertical height of image on the screen may not be

properly displayed.

1. Enter the Service mode. (See page 1-6-1.)

Press [9] button on the remote control unit and

select V-S mode. (Press [9] button then display will

change to V-P and V-S).

2. Input monoscope pattern and leave it for at least 20

minutes.

3. Press [PROG+/PROG-] buttons on the remote con-

trol unit so that the monoscope pattern is 90

±

5% of

display size and the circle is round.

6. V. Shift Adjustment

Purpose: To obtain correct vertical position of screen

image.

Symptom of Misadjustment: If V. position is incor-

rect, vertical position of image on the screen may not

be properly displayed.

1. Enter the Service mode. (See page 1-6-1.)

Press [9] button on the remote control unit and

select V-P mode. (Press [9] button then display will

change to V-P and V-S).

2. Input monoscope pattern and leave it for at least 20

minutes.

3. Press [PROG+/PROG-] buttons on the remote con-

trol unit so that the top and bottom of the mono-

scope pattern are equal to each other.

7. H. Shift Adjustment

Purpose: To obtain correct horizontal position and

size of screen image.

Symptom of Misadjustment: Horizontal position and

size of screen image may not be properly displayed.

1. Enter the Service mode. (See page 1-6-1.)

Press [8] button on the remote control unit and

select H-P mode.

2. Input monoscope pattern and leave it for at least 20

minutes.

3. Press [PROG+/PROG-] buttons on the remote con-

trol unit so that the left and right side of the mono-

scope pattern are equal to each other.

4. Turn the power off and on again.

8. Cut-off Adjustment

Purpose: To adjust the beam current of R, G, B, and

screen voltage.

Symptom of Misadjustment: White color may be

reddish, greenish or bluish.

Notes:

Screen Control (FBT) --- H.V./Power Supply CBA

FBT= Fly Back Transformer

Use the Remote Control Unit

1. Degauss the CRT and allow CRT to operate for 20

minutes before starting the alignment.

2. Set the screen control to minimum position. Input

the Black raster signal from RF (or Ext.) input.

3. Enter the service mode. (See page 1-6-1.)

Dimmed horizontal line appears on the CRT.

4. To enter the C/D/S mode, press the [VOL-] button

on the remote control unit.

5. To enter the CUT OFF (R) mode, press [1] button

on the remote control unit.

6. Turn the screen control up until dimmed horizontal

line appears.

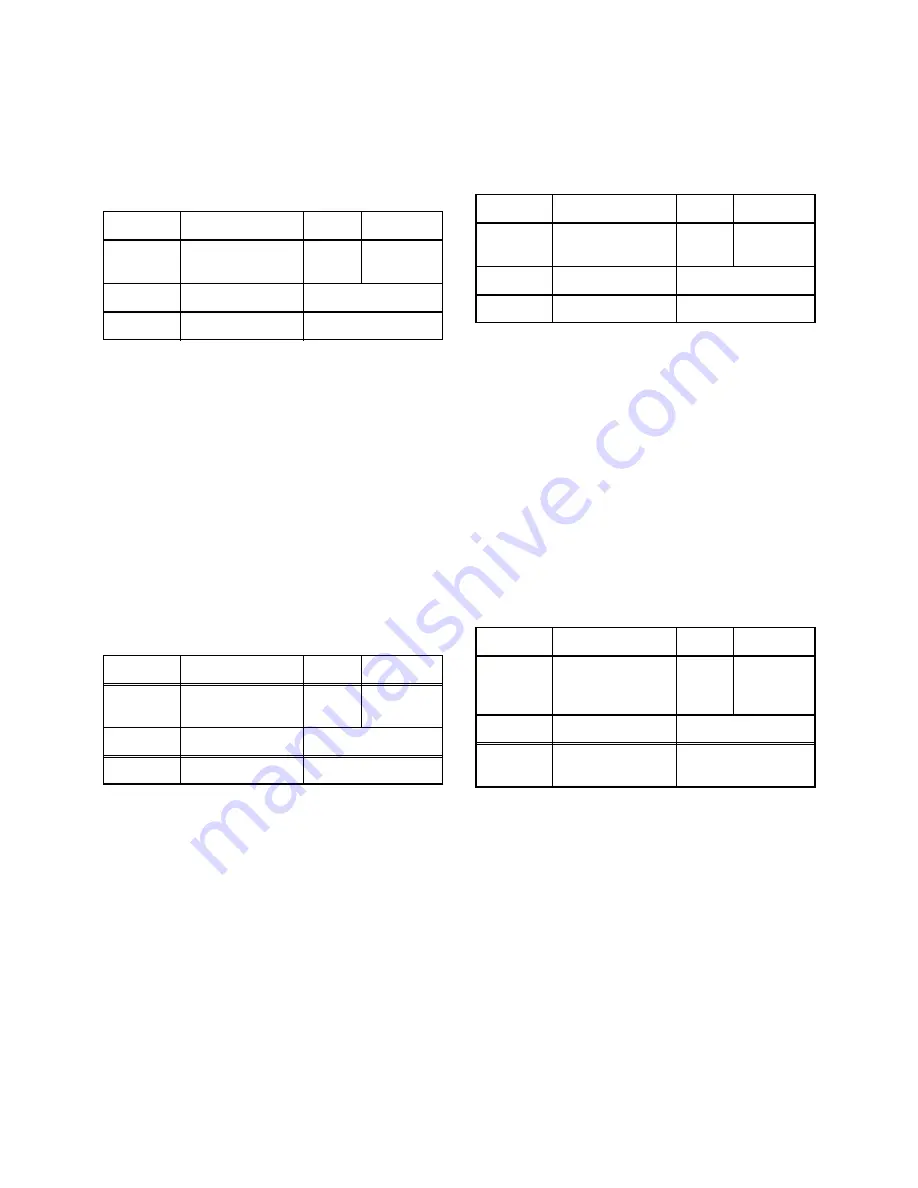

Test point

Adj. Point

Mode

Input

Screen

PROG+/PROG-

buttons

RF

(or Ext.)

Monoscope

Tape

M. EQ.

Spec.

---

Pattern Generator

90

±

5%

Test point

Adj. Point

Mode

Input

Screen

PROG+/PROG-

buttons

RF

(or Ext.)

Monoscope

Tape

M. EQ.

Spec.

---

Pattern Generator

90

±

5%

Test point

Adj. Point

Mode

Input

Screen

PROG+/PROG-

buttons

RF

(or Ext.)

Monoscope

Tape

M. EQ.

Spec.

---

Pattern Generator

90

±

5%

Test point

Adj. Point

Mode

Input

Screen

Screen-Control,

PROG+/PROG-

buttons

RF

(or Ext.)

Black Ras-

ter

Tape

M. EQ.

Spec.

---

Pattern Generator

See Reference

Notes below

Summary of Contents for TVC5044

Page 17: ...1 5 4 T6627DC Fig 4 S 11 S 11 S 11 S 11 Anode Cap 11 CRT CRT CBA...

Page 36: ...Main 1 5 Schematic Diagram 1 8 3 1 8 4 T6627SCM1...

Page 37: ...Main 2 5 Schematic Diagram 1 8 5 1 8 6 T6627SCM2...

Page 38: ...Main 3 5 Schematic Diagram 1 8 7 1 8 8 T6627SCM3...

Page 39: ...Main 4 5 Schematic Diagram 1 8 9 1 8 10 T6627SCM4...

Page 40: ...1 8 11 1 8 12 T6627SCM5 Main 5 5 Schematic Diagram...

Page 42: ...1 8 15 1 8 16 H V Power Supply 2 2 Schematic Diagram T6627SCP2...

Page 43: ...1 8 17 1 8 18 T6627SCCRT CRT Schematic Diagram...

Page 44: ...1 8 19 1 8 20 T6627SCT Text Schematic Diagram...

Page 53: ...1 14 3 T6627PEX Packing S3 S6 X3 S2 X4 X1 TAPE S1 FRONT S4 X2 3 X2 7 X2 14 X2 15...

Page 86: ...2 4 9 Z13PDA Fig DM16 43 41 42 L 13 Fig DM17 44 45 Slide P 9...