4

Place the heater on solid masonry or solid concrete. When

the heater is used on a combustible floor, use an Underwrit-

ers Listed floor protector. The floor protector must comply

with UL Standards.The base should extend at least 16"

beyond the door of the heater and should extend under the

flue pipe if it is elbowed towards a wall

(Fig. 5).

CAUTION!

KEEP FURNISHINGS AND OTHER

COMBUSTIBLE MATERIALS

AWAY FROM THE HEATER.

MINIMUM CLEARANCE

TO COMBUSTIBLE WALLS

Installation

FLOOR

PROTECTOR

FLOOR

PROTECTOR

FIG. 2

(60"

MIN

.)

18"

FIG. 3

Uncrate and/or unpack the heater, removing all pack-

ing material, being careful not to dispose of the Parts

Bag.

Open the front feed door and remove the parts from

inside the stove. You should find the following: Hearth

Plate (1); Solid Damper (1); Lids (2); Pivoting Top (1);

Lid Support (1); Parts Package (1) containg nuts,

bolts, door handle, door latch and securing harware;

Legs (4); Cast Iron Collar (1); Cast Iron Damper (1);

Baffle Assembly (1); Lid Lifter (1).

Place cardboard or other soft material adjacent to the

stove and carefully turn the stove onto its top side

(bottom facing up).

Attach hearth plate to the front of the stove in its proper

location.

Attach both rear and front legs to the stove. Tighten

the nuts and bolts securely. The stove may now be

CAREFULLY turned over to stand on its four legs.

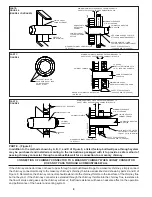

Attach the baffle assembly and flue collar to the stove

by inserting the baffle studs thru the two holes located

on the top of the rear of the stove; place the flue collar

over the studs and mount using the proper nuts and

washers. Place lid support and lid in position on

pivoting top. Place the slide damper in position on the

top of the hearth plate and under the feed door, and

secure with screw in slot.

After consulting the installation instructions for mini-

mum clearances to combustibles, locate your floor

protector accordingly and carefully place the stove in

your selected location. Install stove pipe, elbows and

thimble as necessary, utilizing either a recently cleaned

and inspected masonry chimney (properly lined) or a

UL Listed chimney. Insure that the damper provided

is installed in the flue collar.

Again, check the following illustrations and be sure

you have the clearances shown from the heater and

the connector pipe to combustible surfaces. If you

have a solid brick or stone wall behind your heater,

you may place your heater as close as you wish to the

wall. However, if the wall is only faced with brick or

stone, consider it a combustible wall.

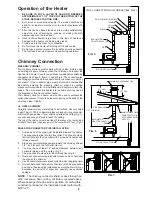

If your chimney drafts excessively, purchase and use

a Barometric Draft Regulator (DR6 available from

factory).

The chimney connection should be as short as pos-

sible, and the heater must have its own flue. Do not

connect this unit to a chimney flue serving other

appliances.

Use three sheet metal screws in each stove pipe and

or elbow joint to firmly hold the pipe together.

Do not install this heater in a mobile home or trailer.

Check your local building and insurance codes. The

installation must comply with their rulings.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

34"

865mm

26"

660mm

28"

712mm

28"

712mm

20"

508mm

37-1/2"

953mm

458mm

HEATER/FLOOR PROTECTOR LOCATION

(Dimensions are required for non-protected surfaces.

See chart for dimensions for protected surfaces.)

FLOOR

PROTECTOR

BACK WALL

DASHED LINES

SHOW STRAIGHT

OUT CHIMNEY

CONNECTOR

6"

153mm

60"

34"

865mm

26"

660mm

NON- COMBUSTIBLE

CONSTRUCTION IN

ACCORDANCE WITH

NFPA 211

Protected Surfaces (NFPA 211)

Parallel

Corner

Side

Rear

12-inches

12-inches

12-inches

305-mm

305-mm

305-mm

6"

153mm

16"

407mm

28-3/4"

730mm

6"

153mm

FIG. 4

28"

204mm

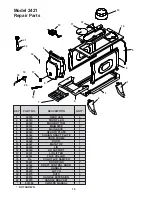

Summary of Contents for LOGWOOD 2421

Page 11: ...NOTES 11 ...