66339-BIM-C-0206

2

Unitary Products Group

IMPROPER INSTALLATION MAY CREATE A

CONDITION WHERE THE OPERATION OF

THE PRODUCT COULD CAUSE PER-

SONAL INJURY OR PROPERTY DAMAGE.

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTE-

NANCE CAN CAUSE INJURY OR PROP-

ERTY DAMAGE. REFER TO THIS MANUAL

FOR ASSISTANCE OR ADDITIONAL

INFORMATION, CONSULT A QUALIFIED

INSTALLER, SERVICE AGENCY OR THE

GAS SUPPLIER.

THIS PRODUCT MUST BE INSTALLED IN

STRICT COMPLIANCE WITH THE

ENCLOSED INSTALLATION INSTRUC-

TIONS AND ANY APPLICABLE LOCAL,

STATE, AND NATIONAL CODES INCLUD-

ING BUT NOT LIMITED TO, BUILDING,

ELECTRICAL AND MECHANICAL CODES.

TABLE OF CONTENTS

NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

NOTES, CAUTIONS AND WARNINGS . . . . . . . . . . . . . . . . 4

REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

BLOWER MOTOR MOUNTING LOCATIONS . . . . . . . . . . . 5

MOTOR MOUNT ARRANGEMENTS. . . . . . . . . . . . . . . . . . 5

AIR DISCHARGE CONVERSION . . . . . . . . . . . . . . . . . . . . 6

AIR DISCHARGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

UNIT INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

DUCT CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

INSULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SUPPLY AIR DUCTS . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

RETURN AIR DUCT ANGLES . . . . . . . . . . . . . . . . . . . . 11

DRAIN CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 11

REFRIGERANT MAINS . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

EVAPORATOR SECTION PIPING . . . . . . . . . . . . . . . . . 12

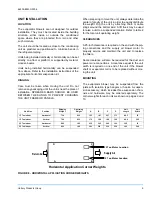

SUPPLY AIR BLOWER ADJUSTMENT. . . . . . . . . . . . . . . 12

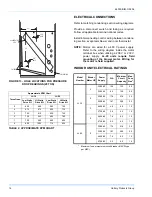

ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . 14

INDOOR UNIT ELECTRICAL RATINGS . . . . . . . . . . . . . . 14

LIST OF FIGURES

Fig.

Pg.

Product Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . 3

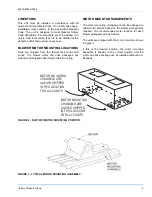

Factory Motor Mounting Position . . . . . . . . . . . . . . . . . 5

Typical Motor Mounting Assembly . . . . . . . . . . . . . . . . 5

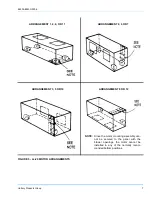

Ll-15 Motor Arrangements . . . . . . . . . . . . . . . . . . . . . . 6

Ll-20 Motor Arrangements . . . . . . . . . . . . . . . . . . . . . . 7

Vertical Airflow Arrangements . . . . . . . . . . . . . . . . . . . 8

Horizontal Airflow Arrangements . . . . . . . . . . . . . . . . . 8

Horizontal Application Corner Weights . . . . . . . . . . . . 9

Vertical Application Corner Weights

(See Table On Page 9 For Weights) . . . . . . . . . . . . . 10

Suggested Method For Connecting Ductwork . . . . . . 11

Recommended Drain Piping . . . . . . . . . . . . . . . . . . . 11

Pressure Drop Across Indoor Coil (15 Ton). . . . . . . . 15

Pressure Drop Across Indoor Coil (20 Ton). . . . . . . . 15

15 Ton Blower Performance . . . . . . . . . . . . . . . . . . . 17

20 Ton Blower Performance . . . . . . . . . . . . . . . . . . . 17

Unit Dimensions Ll-15 And Ll-20 . . . . . . . . . . . . . . . . 18

Piping And Electrical Connection Locations . . . . . . . 19

LIST OF TABLES

Tbl.

Pg.

Physical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

approximate rpm chart . . . . . . . . . . . . . . . . . . . . . . . . 14

LL-15 15 Ton AirFlow. . . . . . . . . . . . . . . . . . . . . . . . . 16

LL-20 20 Ton Airflow . . . . . . . . . . . . . . . . . . . . . . . . . 16

Unit Dimensions lL-15 and lL-20 . . . . . . . . . . . . . . . . 18

6

Piping And Electrical Connection Sizes . . . . . . . . . . . 19