035-18575-001-A-1102

Unitary Products Group

21

START-UP

CRANKCASE HEATER

The crankcase heater must be energized at least 8

hours before starting the compressor. To energize the

crankcase heater, the main disconnect switch must be

closed. During this 8 hour period, the system switch on

the room thermostat must be “OFF” to prevent the

compressor from starting. Make sure that the bottom of

the compressor is warm to the touch to prove crank-

case heater operation.

PRE-START CHECK

Before starting the unit, complete the following check

list:

1.

Have sufficient clearances been provided?

2.

Has all foreign matter been removed from the inte-

rior of the unit (tools, construction or shipping

materials, etc.)?

3.

Have the condenser fans been rotated manually to

check for free rotation?

4.

Are all wiring connections tight?

5.

Does the available power supply agree with the

nameplate data on the unit?

6.

Is the control circuit transformer set for the proper

voltage?

7.

Have the fuses, disconnect switch and power wire

been sized properly?

8.

Are

all

compressor

hold-down

nuts

properly

secured?

9.

Are any refrigerant lines touching each other or any

sheet metal surface? Rubbing due to vibration

could cause a refrigerant leak.

10. Are there any visible signs of a refrigerant leak,

such as oil residue?

11. Is any electrical wire laying against a hot refrigerant

line?

INITIAL START-UP

1.

Supply power to the unit through the disconnect

switch at least 8 hours prior to starting the com-

pressor.

2.

Move the system switch on the thermostat to the

AUTO or COOL position.

3.

Reduce the setting of the room thermostat to ener-

gize the compressor.

4.

Check the operation of the evaporator unit per the

manufacturer’s recommendations.

5.

With an ammeter, check the compressor amps

against the unit data plate.

6.

Check for refrigerant leaks.

7.

Check for any abnormal noises and/or vibrations,

and make the necessary adjustments to correct fan

blade(s) touching shroud, refrigerant lines hitting

on sheet metal, etc.

8.

After the unit has been operating for several min-

utes, shut off the main power supply at the discon-

nect

switch

and

inspect

all

factory

wiring

connections and bolted surfaces for tightness.

OPERATION

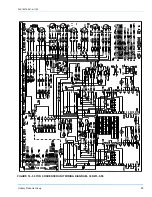

NOTE: The timing intervals described in the following

procedures are nominal. Some variations will

naturally occur due to differences in individual

components, or due to variations in ambient

temperature or line/control voltage. Refer to

the wiring labels inside of the unit control

access panel for additional information.

SEQUENCE OF OPERATION

OVERVIEW

These series of condensing units, come factory

equipped with Simplicity

controls to monitor all unit

functionality and safety controls.

Do not attempt to start the compressor without

at least 8 hours of crankcase heat or compres-

sor damage can occur.