66832-UIM-D-1205

12

Unitary Products Group

GAS PIPING INSTALLATION

Properly sized wrought iron, approved flexible or steel pipe must be

used when making gas connections to the unit. If local codes allow the

use of a flexible gas appliance connection, always use a new listed con-

nector. Do not use a connector that has previously serviced another gas

appliance.

Some utility companies or local codes require pipe sizes larger than the

minimum sizes listed in these instructions and in the codes. The furnace

rating plate and the instructions in this section specify the type of gas

approved for this furnace - only use those approved gases. The instal-

lation of a drip leg and ground union is required. Refer to Figure 17.

IMPORTANT: An accessible manual shutoff valve must be installed

upstream of the furnace gas controls and within 6 feet (1.8 m) of the fur-

nace. Refer to Figures 14, 15, and 16.

The furnace must be isolated from the gas supply piping system by

closing its individual external manual shutoff valve during any pressure

testing of the gas supply piping system at pressures equal to or less

than 1/2 psig (3.5 kPa).

Gas piping may be connected from either side of the furnace using any

of the gas pipe entry knockouts on both sides of the furnace. Refer to

Figure 5 dimensions.

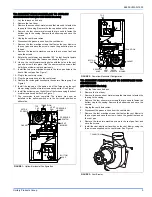

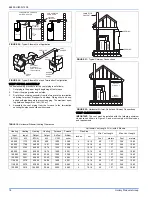

FIGURE 14: Upflow Configuration (50-125 MBH Model Only)

FIGURE 15: Downflow Configuration (50-125 MBH Model Only)

CHECKING THE GAS PRESSURES

1.

The pressure ports on the gas valve are marked OUT P and IN

P.

2.

The manifold pressure must be taken at the port marked OUT P.

3.

The inlet gas supply pressure must be taken at the port marked

IN P.

4.

Using a 3/32” (0.2 cm) Allen wrench, loosen the set screw by

turning it 1 turn counter clockwise. DO NOT REMOVE THE

SET SCREW FROM THE PRESSURE PORT.

5.

Push one end the 3/8” (0.9 cm) ID flexible tubing over the pres-

sure port so that the body of the port is inside the tubing.

6.

Use a reducer connector to connect the 3/8” (0.9 cm) ID flexible

tube to a 1/4” (0.9 cm) ID flexible tube that is connected to a "U”

tube manometer or digital pressure measuring equipment.

IMPORTANT: The inlet gas pressure operating range table specifies

what the minimum and maximum gas line pressures must be for the

furnace to operate safely. The gas line pressure MUST BE a mini-

mum of:

•

7” W.C. (1.74 kPA) for Natural Gas

•

11” W.C. (2.74 kPA) for Propane (LP) Gas

in order to obtain the BTU input specified on the rating plate and/or

the nominal manifold pressure specified in these instructions and on

the rating plate.

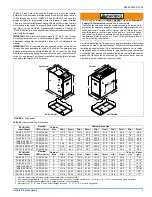

TABLE 6: Inlet Gas Pressure Range

INLET GAS PRESSURE RANGE

Natural Gas

Propane (LP)

Minimum

4.5” W.C. (1.12 kPa)

8.0” W.C. (1.99 kPa)

Maximum

10.5” W.C. (2.61 kPa)

13.0” (3.24 kPa) W.C.

BLOWER

DOOR

SWITCH

ROLL-OUT

SWITCHES

BURNERS

HOT

SURFACE

IGNITOR

GAS

VALVE

PRESSURE

SWITCH

GAS

PIPE

GAS

SHUT-OFF

VALVE

ROLL-OUT

SWITCH

DIRT

LEG

VENT

BLOWER

FURNACE

CONTROL

BLOWER

DOOR

SWITCH

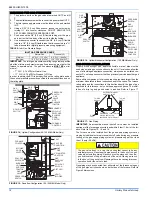

ROLL-OUT

SWITCHES

BURNERS

HOT

SURFACE

IGNITOR

GAS

VALVE

PRESSURE

SWITCH

VENT

VENT PIPE

TRANSITION

GAS

PIPE

3” DIAMETER

VENT PIPE

GAS

SHUT-OFF

VALVE

ROLL-OUT

SWITCH

DIRT LEG

VENT

BLOWER

FURNACE

CONTROL

FIGURE 16: Upflow/Horizontal Configuration (150 MBH Model Only)

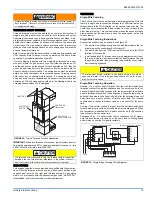

FIGURE 17: Gas Piping

The gas valve body is a very thin casting that cannot take any

external pressure. Never apply a pipe wrench to the body of the gas

valve when installing piping. A wrench must be placed on the octa-

gon hub located on the gas inlet side of the valve. Placing a wrench

to the body of the gas valve will damage the valve causing improper

operation and/or the valve to leak.

BLOWER

DOOR

SWITCH

ROLL-OUT

SWITCHES

BURNERS

HOT

SURFACE

IGNITOR

GAS

VALVE

PRESSURE

SWITCH

GAS

PIPE

GAS

SHUT-OFF

VALVE

ROLL-OUT

SWITCH

DIRT

LEG

VENT

BLOWER

FURNACE

CONTROL

EXTERNAL MANUAL

SHUTOFF VALVE

TO GAS

SUPPLY

TO GAS

SUPPLY

GROUNDED JOINT UNION

MAY BE INSTALLED

INSIDE OR OUTSIDE UNIT.

DRIP

LEG