035-18877-001-B-0203

8

Unitary Products Group

DUCT CONNECTIONS

All ducts should be designed and installed in accordance with

all national and/or local codes.

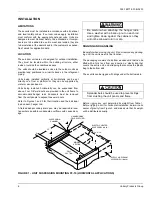

Refer to Figure 3 for suggested method of connecting supply

air ductwork.

Ducts should be sized no smaller than the duct flanges on the

unit or the electric heater (if used). Refer to the unit dimen-

sions (Figure 15) and heater detail (Figure 4) for these sizes.

Refer to Form 035-16602-001 for installation instructions on

the electric heater.

Use flexible fiber glass, plastic cloth collars or other nonflam-

mable material at the unit duct connections to minimize the

transmission of noise and vibration.

Insulate all ductwork running through the unconditioned

areas to prevent moisture condensation and to provide more

economical operation.

The return air duct flange is factory-mounted on the front of

the unit, but it can be reversed with the solid bottom panel for

horizontal applications. When the return air grille is used, the

duct connection frame is not used.

A supply air plenum (Figure 7), a base (Figure 6) and a return

air grille (Figure 5) are available as field-installed accesso-

ries, and one of the following respective instructions will be

packed with each.

• Form 035-16650-001 - Supply Air Plenum

• Form 035-16621-001 - Return Air Grille

• Form 035-16632-001 - Base

The supply air plenum and the return air grille should be used

in lieu of ductwork only when a free blow/free return applica-

tion is practical.

FIGURE 3 - SUPPLY AIR DUCT CONNECTIONS

AIR

OUT

NON-FLAMMABLE

COLLAR

FLANGEDDUCT

CONNECTION

(FIELD

FABRICATED)

DUCT

SUPPLYAIR

DUCTFLANGE

BLOWERGASKET

(BYINSTALLER)

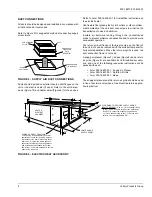

FIGURE 4 - ELECTRIC HEAT ACCESSORY

HEATER

ELEMENT

CHAMBER

3/4

A

C

1

D

L

E

F

M

G

H

K

B

ACCESS OPENING FOR POWER SUPPLY WIRING

1/2

WIRING HARNESS LOCATION

This opening in the bottom of the heater

control box is used for the wiring harness

that connects the heater accessory to the

basic unit. It is provided with a squeeze

connector for securing the wiring harness,

and its location corresponds to the loca-

tion of the 1-23/32 inch knockout in the top

panel of the basic unit.

CONTROL BOX

ACCESS PANEL

10KW THRU 30KW - Add a 1-1/4 inch conduit fitting

to the 1-23/32 inch hole for wire sizes up through

#1 A

W

G. Remove the knockout ring and add a

1-1/2 inch conduit fitting to the 1-31/32 inch hole

for wire sizes up through #0 AWG.