035-18877-001-B-0203

Unitary Products Group

11

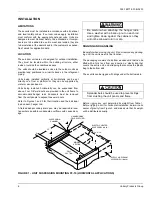

Before brazing the refrigerant lines to these connections,

remove the short panel from the unit frame and slide it (along

with the grommets) onto the refrigerant lines. After the brazed

joints have cooled, slide the panel back into place and secure

it to the unit frame.

NOTE:

These units can only be piped from one side of the

unit.

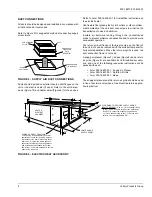

EXPANSION VALVE BULB

The expansion valve bulb must be fastened in a 10 or 2

o'clock position to the suction line outside the cabinet after

the piping connections have been made.

Use the clamps provided with the valve to secure the bulb in

position. Bulb must be insulated with armaflex or mastic to

assure proper operation.

NOTE:

These coils can only be piped from one side of the

unit.

TABLE 5: ELECTRICAL DATA - FF-10

Blower

Motor HP

Power Supply

FLA

Max. Fuse

Size

1

AMPS

1.

Dual element, time delay fuses.

2

208-3-60

7.5

15

230-3-60

6.8

15

460-3-60

3.4

15

Note: Refer to Form 035-16602-001 for electrical data on units equipped

with an electric heat accessory.

TABLE 6: ELECTRICAL DATA - UNITS WITH ELECTRIC HEAT

Model Basic Unit

1

Nominal Heater

KW

2

Power Supply

Voltage

3

Full Load Amps

Total Ampacity,

Amps

Max. Fuse Size

4

,

Amps

Heater

Blower Motor

120

10

208

20.8

7.5

35.4

35

230

24.1

6.8

37.3

40

460

12.0

3.4

19.2

20

16

208

33.3

7.5

51.1

50

230

38.5

6.8

54.6

60

460

19.2

3.4

26.1

30

26

208

54.1

7.5

77.1

80

230

62.5

6.8

83.4

90

460

31.3

3.4

41.7

45

36

208

74.9

7.5

103.2

110

230

86.6

6.8

112.2

125

460

43.3

3.4

56.1

60

1.

Units with an electric heat accessory will always be wired for a single power supply.

2.

Refer to the HEATING CAPACITY table for the actual KW and MBH ratings of each heater at the different voltages.

3.

All voltages are for 3-phase, 60 hertz operation.

4.

Inverse time circuit breakers may be used in lieu of dual element, time delay fuses.