035-16626-000-E-0103

Unitary Products Group

11

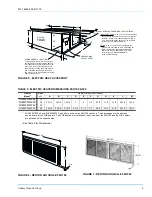

The return air duct flange is factory-mounted on the

front of the unit.

A supply air plenum (Figures 6 and 7), a base (Figures

8 and 9) and a return air grille (Figure 7) are available

as field-installed accessories, and one of the following

respective instructions will be packed with each.

•

Form 035-16650-001 - Supply Air Plenum

•

Form 035-16621-001 - Return Air Grille

•

Form 035-16632-001 - Base Accessory

The supply air plenum and the return air grille should

be used in lieu of ductwork only wen a free blow/free

return application is practical.

REFRIGERANT MAINS

Many service problems can be avoided by taking ade-

quate precautions to provide and internally clean and

dry system and by using procedures and materials that

conform with established standards.

Use hard drawn copper tubing where no appreciable

amount of bending around pipes or other obstructions

is necessary. Use long radius ells wherever possible

with one exception - small radius ells for any traps in a

vapor riser. If soft copper is used, care should be

taken to avoid sharp bends which may cause a restric-

tion.

Fiber glass insulation and a sealing material such as

permagum should be packed around refrigerant lines

where they penetrate a wall to reduce vibration and to

retain some flexibiltiy.

Support all refrigerant lines at minimum intervals with

suitable hangers, brackets or clamps.

Braze all copper to copper joints with Sil-Fos 5 or

equivalent brazing material.

DO NOT USE SOFT

SOLDER

.

Never braze or solder the liquid and vapor lines

together for support purposes, they must be completely

insulated, one from the other.

Refer to the installation instructions (035-16192-001)

for the matching outdoor unit for piping limitations, line

sizes and other design considerations.

INSTALLING REFRIGERANT MAINS

The units are evacuated and dehydrated at the factory

and shipped with a holding charge of Refrigerant-22.

The vapor and liquid connections are sealed with cop-

per discs.

If the unit has already lost its holding charge, it should

be leak tested and the necessary repairs should be

made, if the unit has maintained its holding charge, you

can assume that it has no leaks and proceed with the

installation.

The temperature required to make or break a brazed

joint is sufficiently high to cause oxidation of the copper

unless an inert atmosphere is provided.

Make sure the refrigerant in the lines has been recov-

ered then drill a small hole through the discs to prevent

any internal pressure from blowing them off and to

allow the flow of dry nitrogen through the connections

when unbrazing the closures.

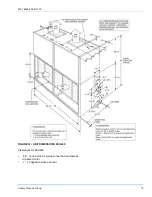

The liquid and vapor connections must be piped out-

side the unit. Refer to the unit drawings for the loca-

tions and the dimensions of these connections.

Before brazing the refrigerant lines to these connec-

tions, remove the short panel from the unit frame and

slide the grommets onto the refrigerant lines. After the

brazed joints have cooled, slide the grommets back

into place and secure the panel to the unit frame.

NOTE: These coils can only be piped from one side of

the unit.

DRAIN CONNECTION

The drain line MUST be trapped because the coil is

located on the negative side of the supply air blower,

and it must be protected from freezing temperatures.

A 7/8” OD drain connections extends through right

hand side of the cabinet. Refer to Figure 13 for recom-

mended drain piping.

The drain connection is located on the same side of the

unit as the refrigerant connections. The line should be

insulated where moisture drippage will be objection-

able or cause damage to the area.