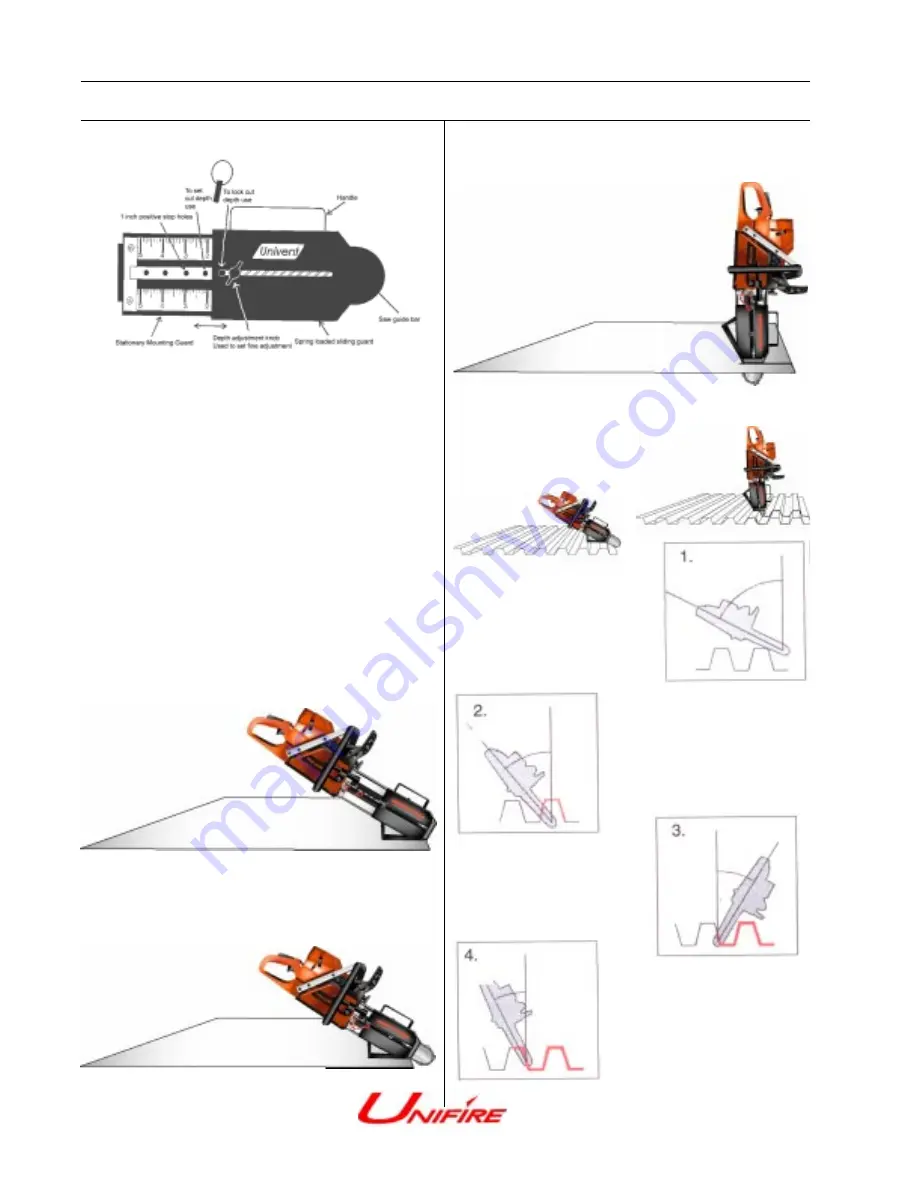

Depth Guage Instructions

Depth Guage Instructions

1. Using the positive stop pin set your cut depth and

lock into position.

2. Position saw at a 30 degree angle. (This angle is

preset on your depth guage.)

3. For a standard cut push saw bar and chain into

cut area, the guage will automatically slide back to

your predetermined cut depth.

4. Once the cut has been started move saw to a 90

degree angle to achieve a precise cut at desired

depth.

The depth guage is spring loaded. For a standard

cut, simply push saw bar and chain into cut area, the

guage will automatically slide back. When the saw is

pulled out of the cut then the depth guage automati-

cally springs forward to cover the bar and chain.

The pin can be positioned in a hole to set a plunge

depth or can be set in a locked position to hold a

specified cutting depth.

Application

1. Position saw at a 30 degree

angle, at the highest point.

2.Continue following the line of

the roof, maintaining the same

pattern.

Corrugated Roofs

3.Tilt saw to maintain the

angle in relation to the saw

and cutting surface.

3.Always maintain the angle

which is determined by the

surface angle.

Page 9