35

4.4 - OPERATION OF THE

BOILER

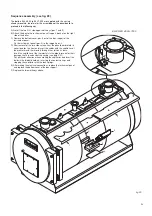

To ascertain that the form and the dimension of

the burner flame, which we estimate very

important, are the correct ones for the good

operation of the boiler, it is suggested to make

a visual inspection of the furnace at least one

month after the first lighting.

The furnace cylinder shall show a homogeneous

coloration for all of its length to demonstrate

that the flame reverses in proximity of the blind

bottom.

Contrarily, a furnace that underlines a clean

distinction of colour among two zones (the

anterior part clearer than the rear part), it would

be the typical example of a flame of inadequate

length, for which the adjustment of the burner,

to avoid located overheatings, with consequent

probable serious damages, needs to be

immediately revised.

Similarly, the state of the exchange surfaces on

the water side, where possible, i.e. on the boi-

lers beginning from the model ELL 1100,

standard equipped with inspection hand holes,

and in the case the presence of limestone,

sludges or deposits is found, the opportune

provisions to seek of it and to eliminate its causes

must be taken.

Such control must be effected within the first

months of exercise of the boiler, in any case

compulsorily to the first stop of the heating

system, at the end of the heating season or on

the occasion of standstills for other extraordinary

interventions, particularly in the case of heating

systems with large water content.

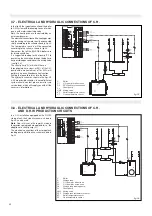

The HIGH EFFICIENCY ELLPREX boilers are

forseen to operate with a return water

temperature never below 54 °C when opera-

ted on light oil, and never below 59 °C when

operated on gas, to avoid (or, at least, to

reduce) the smoke acid condensation

phenomenon, which can be the reason of a

premature deterioration of the steel boiler body.

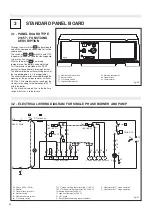

The working thermostat, pos. 32 of the panel

board, must be set at a temperature of

approximately 80 to 85 °C.

The room temperature will be compulsorily

adjusted through a mixing valve and,

eventually, an outer compensator.

To homogenise the water temperature, or avoid

as maximum as possible, returns into the boiler

at a temperature below 54 °C when operated on

oil, or 59°C when operated on gas, a properly

dimensioned shunt pump must be fitted between

flow and return pipes of the boiler.

N.B.The metal sheet corrosion due to the acid

condensate is not covered by the guarantee

because it depends only from the operation of

the C.H. system.

The ELLPREX panel board is equipped with a

low temperature thermostat not allowing the

operation of the pump when the boiler

temperature is below 50 °C (protection against

cold starts).

4.5 - SWITCH OFF OF THE

BOILER

- Switch OFF the burner (switch No.12 to 0

position).

5.1 - GENERAL RULES

Before effecting any operation of cleaning or

maintenance, disconnect the boiler from the

electrical supply acting on the main switch onto

the panel board.

In case of failure or bad operation of the boiler,

switch it off, abstaining your self from any

attempt of reparation or direct intervention.

Exclusively address to professionally qualified

personnel.

The possible reparation of the boiler must be

effected by an authorized service center using

only original spare parts.

The non respect of the above can jeopardize

- Leave the pumps working up to when they are

not stopped by the minimum thermostat.

- Switch Off the power to the boiler panel board.

- If it is decided not to use the boiler for a

MAINTENANCE

the safety of the boiler.

To guarantee the efficiency of the boiler and

for its correct operation it is essential to submit

the boiler to an annual maintenance, through a

professionally qualified technician, according to

the indications of the manufacturer.

When it is decided not to use the boiler

anymore, the parts which can be potential

sources of danger shall be made harmless.

After a month of boiler operation, open the front

door and ascertain the smoke pipes are clean.

In case of a heavy dirtiness:

- Remove the turbulators from smoke pipes.

- Clean all the smoke pipes using the brush

delivered with the boiler.

- Open the two cleaning doors on the sides

of the smoke chamber and remove, with a

vacuum cleaner all the soot.

- Relocate the two cleaning doors and the

turbulators; then close the boiler front door

and check for soundness all around the

sealing rope.

- Then adjust the burner.

Note: With a burner properly adjusted only a

cleanup at the season end is necessary.

5

long period close also the gate valves of

the fuel.

5.2 - ORDINARY

MAINTENANCE

The boiler operating condition are very different

from one case to the other and depend on the

fuel used, on the adjustment of the burner, on

the number of starting, on the C.H. system

characteristics, etc. and for that reason it is

not possible to esthablish, in advance, the

frequence of the maintenances.

It is, then, necessary that the technician, who

performs the first cleaning, esthablish the

cleaning frequency on the base of the boiler

status.

Generally, we suggest the following frequency,

according to the fuel used:

- Gas fired boilers: once a year.

- Oil fired boilers: twice a year or more often

if there is reason to doubte of their

adjustment.

In any case the local rules in force have to

complied with.

We suggest to shake the turbulators, without

removing them from the smoke tubes, at least

once an month of operation, not to allow the soot

blocking them and making them extremely diffi-

cult to be removed.

During the operations of ordinary maintenance

it will be necessary to brush the tube bundle -

after the removal of the turbulators - and the

furnace and collect the soots through the

Summary of Contents for ELLPREX Series

Page 1: ...26739 01 13 rev 4 ELLPREX INSTALLATION USE AND SERVICING INSTRUCTION to be kept by the user...

Page 37: ...37 Notes...

Page 38: ...38 Notes...

Page 39: ...39 Notes...