11

2

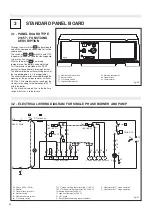

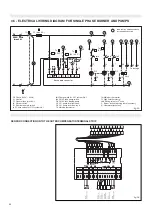

INSTALLATION

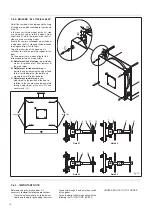

already fitted.

In addition to the a. m. panel board, packaged

in its own carton, in the combustion chamber,

as accessories, there are also:

- a carton containing the flanges for flow,

return and safety connections (if applicable)

with relevant gaskets and bolts, the

cylindrical brush for the cleaning of the

smoke pipes.

- cleaning brush handle extension.

- turbulators extractor.

- ceramic fiber rope for the insulation between

the door and burner blast tube.

- the turbulator cores, only for models ELL

170÷ELL 870 (for their positioning, see table

on page 33).

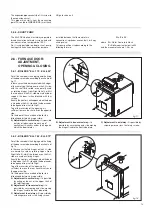

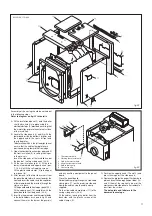

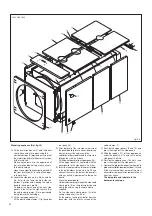

2.2 - HANDLING

The boiler can be moved into position by lifting,

through the upper hooks(s), or by the use of

rollers placed under the strong L profiles of

the basement.

If it necessary, due to the dimensions of the

boiler, it is possible to remove the front door

and the smoke chamber to facilitate the

introduction in the boiler house.

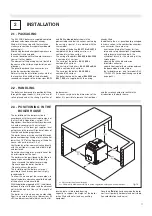

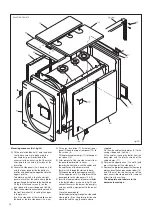

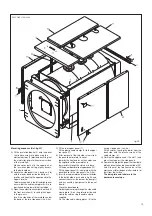

2.3 - POSITIONING IN THE

BOILER HOUSE

The installation of the boiler must be in

accordance with the relevant requirements of

the Gas Safety Regulations, current I.E.E.

Regulations, local water authority bye-laws and

it should also comply with any relevant

requirements of the local gas supplier, local

authority and the relevant Standard Codes of

Practice and building regulations.

The boiler house must be ventilated through

permanent openings having a total surface not

lower than 1/30

th

of the floor area of the boiler

house, with a minimum of 0.5 m

2..

Ventilation by grilles communicating directly

with the outside air is required at both, high

and low levels.

Do not obstruct the grates of aspiration of the

air or dissipation of the heat.

The boiler must be positioned so that there is

enough space available for the following:

- Access around the boiler fore servicing

- Space to open the boiler front door

- Space to access the burner.

The installation of the boiler as close as

possible to the chimeney position is highly

recommended.

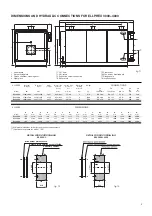

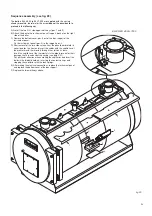

To allow the cleaning of the smoke pipes, in

front of the boiler a clearance equal to the length

of the boiler, has to be available.

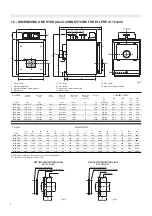

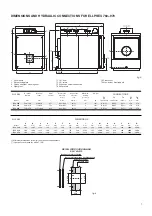

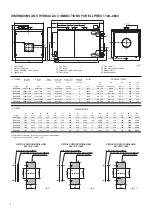

With the boiler door opened at 90°, the distance

between the front of the door and the adjacent

wall must be equal, at least, at the length of

the burner.

The boiler must stand on a non-combustible

floor (i.e. concrete or brick), of dimensions

Q

x

R

(see dimensions table) which must be flat,

x = Not shorter than the boiler body

xx = Sufficient to allow accessibility to all the regulation, safety and control devices.

fig. 16

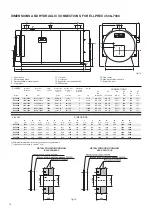

2.1 - PACKAGING

The ELLPREX boilers are supplied complete

with door and smoke chamber already

fitted, whilst the casing with the insulation

matress are contained in separate cardboard

packaging(s).

After having removed every packing make sure

the content is undamaged.

In case of doubt do not use the boiler and revert

your self to the supplier.

The elements of the packing must not be left to

the course of the children as potential sources

of danger.

The panel board and the accessories are

inside the combustion chamber.

Before starting the installation make sure that

the length and the width of the boiler body

received correspond to the dimensions

M, Q

and

R

of the ordered boiler, shown in the

previous tables and that the cartons, containing

the casing, or part of it, are marked with the

same model.

The casing of the boilers

ELL 170

to

ELL 510

,

complete with the insulation matress, is

contained in just one carton.

The casing of the boilers

ELL 630

to

ELL 2200

is contained in 3 cartons.

The casing of the boilers

ELL 2650

is

contained in 4 cartons.

The casing of the boilers

ELL 3000

ed

ELL

3500

is contained in 3 cartons.

The casing of the boilers

ELL 4000

is

contained in 4 cartons.

The boilers between the model

ELL 4500

and

ELL 7000

, are supplied with the casing

level and of a suitable load bearing

capacity to support the weight of the boiler

(when filled with water) and any ancillary

equipment.

Once the installation has been made the boiler

must result perfectly horizontal and well stable

(to avoid vibrations and noise).

Summary of Contents for ELLPREX Series

Page 1: ...26739 01 13 rev 4 ELLPREX INSTALLATION USE AND SERVICING INSTRUCTION to be kept by the user...

Page 37: ...37 Notes...

Page 38: ...38 Notes...

Page 39: ...39 Notes...