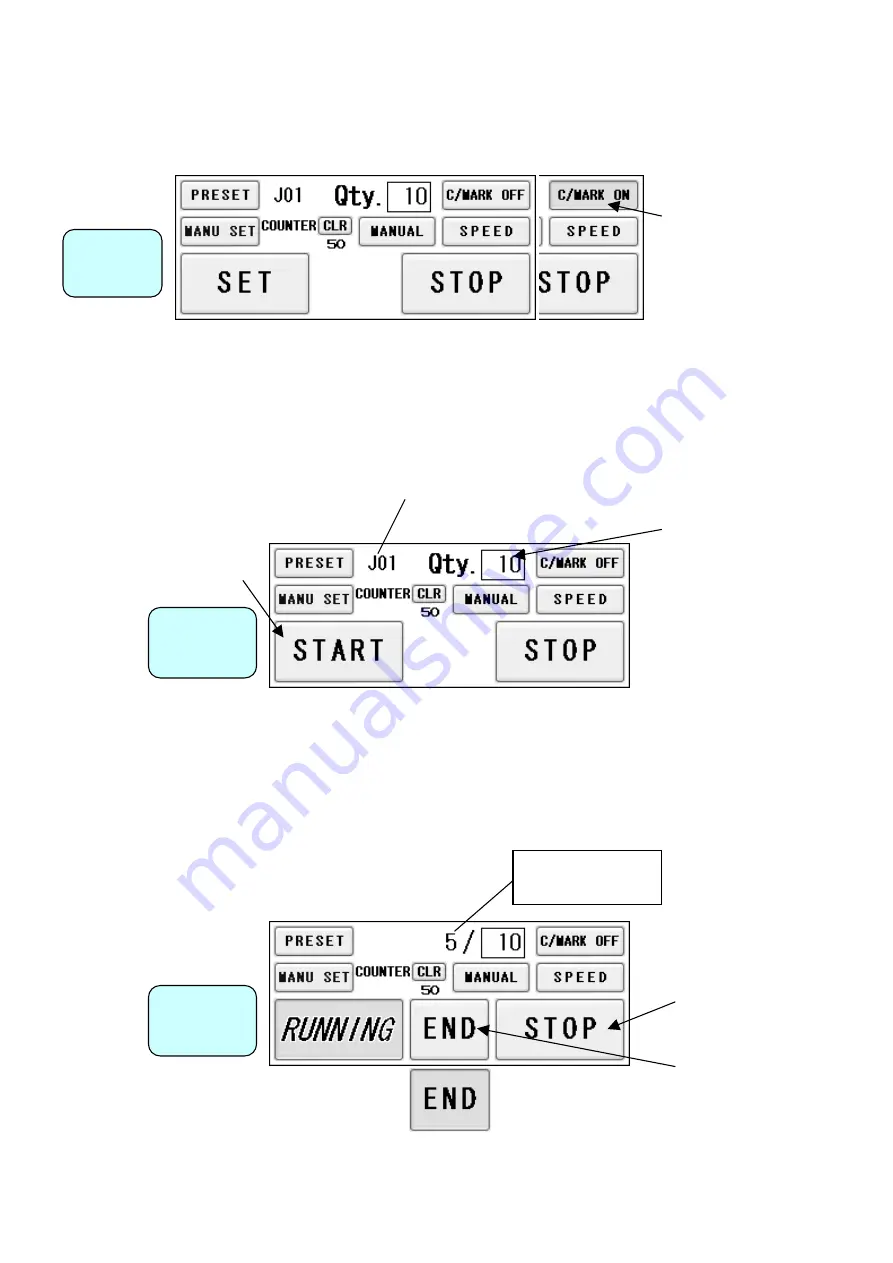

(11) Cut mark on/off selection

Select C/MARK ON to

use cut marks. Select

C/MARK OFF for not

using cut marks.

Operation

Screen

(12) Automatic operation

①

Set the number of sheets for operation. The machine will automatically stop on reaching

the set number. Enter “0” for continuous operations.

User program Job Number you have retrieved is displayed.

Operation

Screen

Enter the number of

sheets for operation.

(Batch Counter) Enter “0”

for continuous

operations.

②

Press START to start an automatic operation. The display will change to RUNNING.

③

Press STOP and the machine will make an EMERGENCY stop even if the operation is

underway.

④

Press END if you wish to stop the machine when the current sheet is completed. The END

sign will blink and the machine will automatically stop upon completion of the work.

Number of sheets

completed

Operation

Screen

26

Summary of Contents for AeroCut

Page 1: ...OPERATION MANUAL UCHIDA YOKO CO LTD TOKYO JAPAN Jul 14 2011 USA ...

Page 38: ...6 Equipment Electric circuit and parts 37 ...

Page 39: ...38 38 ...

Page 40: ...39 39 ...