13

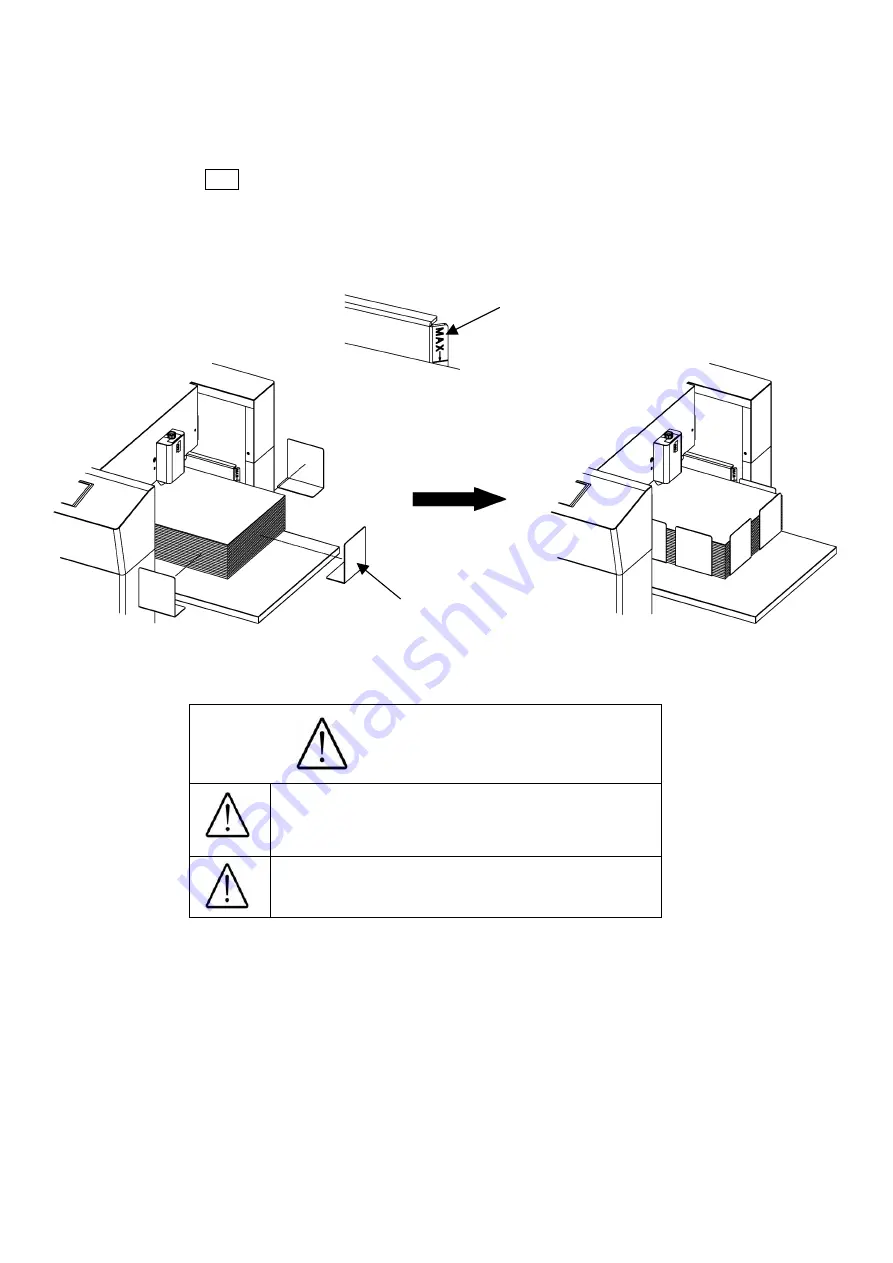

(5) Paper setting

①

Press SET to lower the feed table.

②

Separate the sheets of paper well and place them on the feed table.

③

Fix the paper with the small paper guides.

④

Make sure that the paper stack does not exceed the MAX label.

Caution

Ensure that the paper stack does not

exceed the MAX label, as it may cause

a mechanical failure.

Separate the sheets of paper well, as it

may cause a paper jam.

MAX Label

Paper Guide (Small)

Summary of Contents for AEROCUT G2

Page 1: ...OPERATION MANUAL UCHIDA YOKO CO LTD TOKYO JAPAN Jul 23 2012 USA...

Page 52: ......

Page 53: ...6 Equipment Electric circuit and parts...

Page 54: ......

Page 55: ......

Page 57: ......