UBI EasyCoder 601 – User's Manual

19

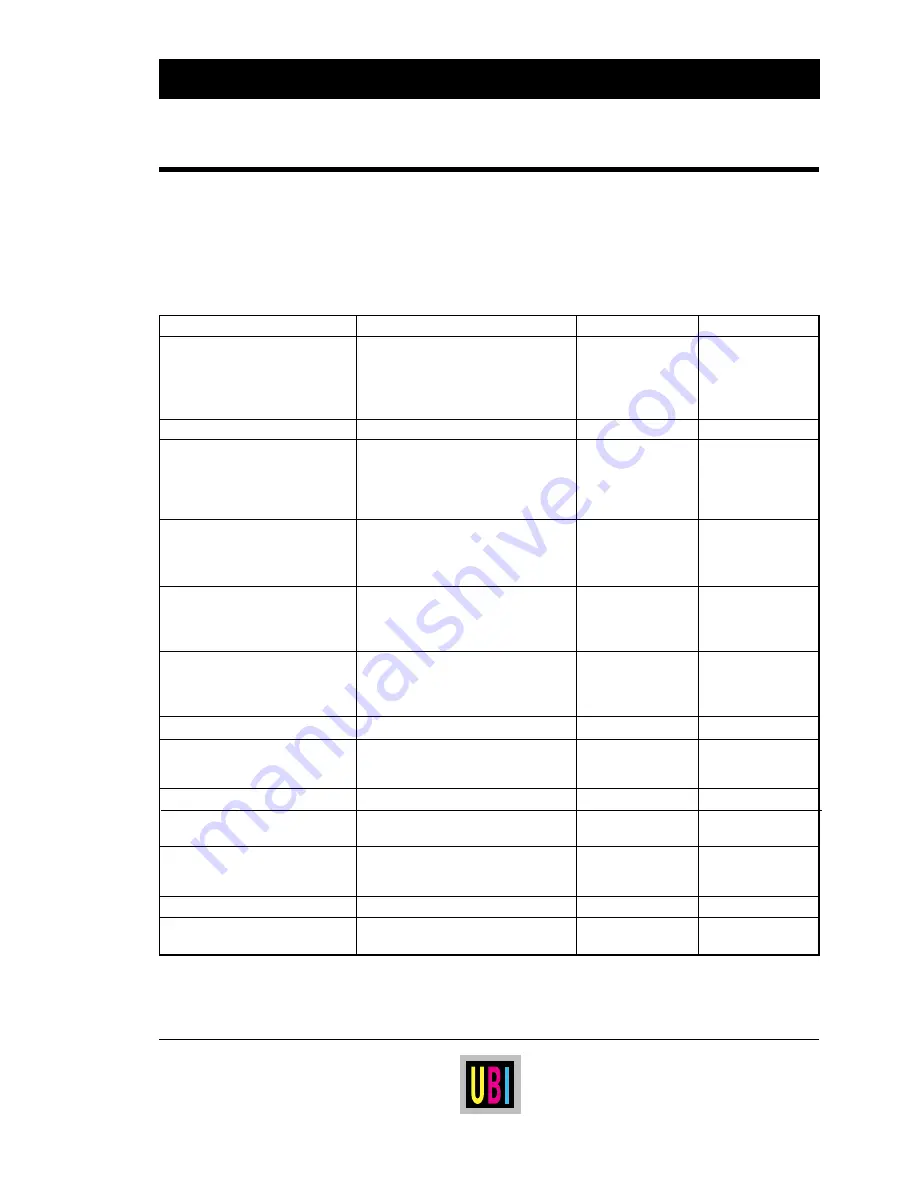

Symptom

Possible Cause

Remedy

Refer to

Overall weak printout

Wrong Paper type setup

Change setup

Technical Manual

Low Contrast setup

Change setup

Technical Manual

Printhead pressure too low

Adjust both knobs

Technical Manual

Worn printhead

Replace printhead

User's Manual

Wrong printhead voltage

Replace CPU board

☎

Call Service

Printout weaker on one side

Uneven printhead pressure

Adjust outer knob

Technical Manual

Weak spots

Foreign particles on paper/ribbon

Clean

n.a.

Paper/ribbon don't match

Use other media

Technical Manual

Poor paper or ribbon quality

Use other media

Technical Manual

Worn printhead

Replace printhead

User's Manual

Worn pressing roller

Check/replace

☎

Call Service

Overall dark printout

Wrong Paper Type setup

Change setup

Technical Manual

Too high Contrast setup value

Change setup

Technical Manual

Printhead pressure too high

Adjust both knobs

Technical Manual

Wrong printhead voltage

Replace CPU board

☎

Call Service

Excessive bleeding

Wrong Paper Type setup

Change setup

Technical Manual

Contrast setup value too high

Change setup

Technical Manual

Printhead pressure too high

Adjust both knobs

Technical Manual

Faulty energy control

Replace CPU board

☎

Call Service

Transfer ribbon breaks

Ribbon fitted around label stop sensor

Reload ribbon

User's Manual

Wrong Paper Type setup

Change setup

Technical Manual

Ribbon unwind unit stuck

Adjust

☎

Call Service

Bad energy control

Check CPU board

☎

Call Service

White parts at transfer printing

Transfer ribbon wrinkled

Adjust

See next paragraph

Transfer ribbon wrinkles

Incorrect paper guide ring adjustment

Adjust

User's Manual

Ribbon obstructed by printhead cable

Clear

n.a.

Too strong printhead pressure

Adjust both knobs

Technical Manual

Dark lines along paper web

Foreign objects on printhead

Clean printhead

User's Manual

White lines along paper web

Printhead dirty

Clean printhead

User's Manual

Missing dots on printhead

Replace printhead

User's Manual

Large part of dot line missing

Wrong X-start or Width setup

Change setup

Technical Manual

Failing printhead

Replace printhead

User's Manual

Failing strobe signal

Check CPU-board

☎

Call Service

Last part of label missing

Too small image buffer

Increase buffer

Technical Manual

Printout missing along inner edge

Bad paper alignment

Adjust

User's Manual

X-start setup value too low

Increase

Technical Manual

TROUBLE SHOOTING

The list below is intended to help the operator to correct possible

printout troubles or flaws in printout quality, and to decide when

assistance from the Service dept. of the nearest UBI distributor

is required. Note that most problems are due to operating errors

or normal wear of the printhead.