USER GUIDE

Control Operation-Service

E3:

Thermistor 3 open.

E4:

Thermistor 4 open (Does not apply to this model).

E5:

Thermistor 1 shorted.

E6:

Thermistor 2 shorted.

E7:

Thermistor 3 shorted.

E8:

Thermistor 4 shorted (Does not apply to this

model).

E9:

Door 2 (lower) open.

P1:

Pump Circuit open (Does not apply to thismodel).

15:

CLEAR ERROR LOG

To clear errors, press and hold (5 seconds) when

CLR is flashing.

16:

THERMISTOR - 1 DIFFERENTIAL

This number should not be adjusted.

17. Does not apply to this model.

18.

THIS NUMBER SHOULD NOT BE ADJUSTED

19.

THIS NUMBER SHOULD NOT BE ADJUSTED

20.

INDIVIDUAL COMPONENT TOGGLE

21.

MODEL NUMBER INDICATOR

Displays the two-digit model number of the specific

unit. See Model list table.

22.

LIGHT ALL LED SEGMENTS

This will illuminate all the LEDs on the display to

ensure they work properly

23.

ACTIVATE DEFROST /HARVEST

-Press and hold for 3 seconds to activate

24.

FACTORY DEFAULTS

-Press and hold for 3 seconds to restore all values to

factory defaults

25.

MAIN SOFTWARE

26. Does not apply to this model

27.

FACTORY TEST MODEL

0 = Off, 1 = On

28.

COMPRESSOR RPM

29.

FREEZE TIME ADJUST (MODEL 54 ONLY)

30.

HARVEST TIME ADJUST (MODEL 54 ONLY)

31.

LOW TEMP ALARM LIMIT (MODEL 55 ONLY)

32.

HIGH TEMP ALARM LIMIT (MODEL 55 ONLY)

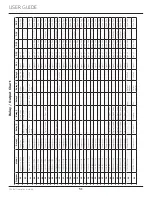

Display #

Relay / Output

- Option #0 – Exit

- Option #1 – Relay 1

- Option #2 – Relay 2

- Option #3 – Relay 3

- Option #4 – Relay 4

- Option #5 – Relay 5

- Option #6 – Relay 6

- Option #7 – DC Output 1

- Option #8 – DC Output 2

- Option #9 – DC Output 3

- Option #10 – DC Output 4

- Option #11 – DC Output 5

- Option #12 – Serial output (Compressor)

SEE RELAY / OUTPUT CHART

49