USER GUIDE

Side-by-Side Installation

u-line.com

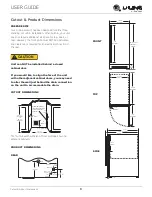

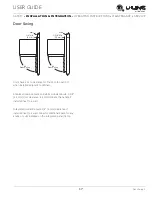

Side-by-Side Installation

Two units may be installed side-by-side.

Cutout width for a side-by-side installation is the cutout

dimension of a single unit times two.

No trim kit is required. However, 1/4" (6 mm) of space

needs to be maintained between the units to ensure

unobstructed door swing.

Units must operate from separate, properly grounded

electrical receptacles placed according to each unit’s

electrical specifications requirements.

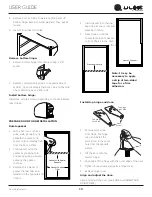

Side-by-Side Installation with Bracket

1. Slide both units out so screws on top of units are easily

accessible.

2. Remove screws as shown below.

3. Place bracket over holes and attach to unit with two

screws removed in step 2 using a T-25 Torx driver.

Tighten screws fully.

4. Gently push units into position. Be careful not to

entangle the electrical cord or water line, if applicable.

5. Re-check the leveling, from front to back and side to

side. Make any necessary adjustments. The unit’s top

surface should be approximately 1/8" (3 mm) below

the countertop.

9