USER GUIDE

Control Operation - Service 2

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE •

SERVICE

VIEWING BIN THERMISTOR SET POINT

To view the set point temperature at which the bin

thermistor will stop ice production, push and release the

up and down arrow icons. Adjustments to this can be

made in the service mode.

SILENT MODE

In some cases it may be requested for the unit to be shut

down temporarily - during meetings for example. To do

this, hold the

and

for three seconds. The unit will

“beep” once and show 3H on the display. This mode can

be canceled by pressing and releasing

. The mode will

automatically be changed back to ON after three hours.

SHOWROOM MODE

This mode is designed to show units in a display environ-

ment. When in this mode the only functions will be the

control and cabinet lights. The compressor, fans, etc. will

not operate. To enter/exit this mode hold the light key

and the power key for 5 seconds. The display will flash

once and beep and the degree symbol will begin to flash.

When the degree symbol is flashing the unit will allow the

use of the control for demonstrations. The unit can be left

in this mode indefinitely.

SERVICE MODE

This mode has options available for service diagnostics.

To enter the mode hold the hidden key for 10 seconds.

The display will show “0.” When in this mode use the up

and down arrows to select the desired option. The LIGHT

key is the ENTER key and will initiate the function. If

changing a setting, you must press the LIGHT key again

to retain the changed setting. To exit the service mode

scroll to option “0” and press the LIGHT key. After five

minutes of not touching any keys the mode will also exit

automatically.

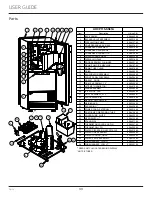

CONTROL FUNCTION GUIDE

FUNCTION

COMMAND

DISPLAY/OPTIONS

ON/OFF

Press

and release

Unit will immediately turn ON or OFF.

Adjust ice thickness

See “Ice” section

Sabbath Mode

See “Sabbath Mode” section

Silent Mode (ice

production suspended for

3 hours)

Hold

and

Display will show “

3H

”.

Clean Mode

See “Cleaning” section

45