PAGE 2 OF 6

0713 IH-707

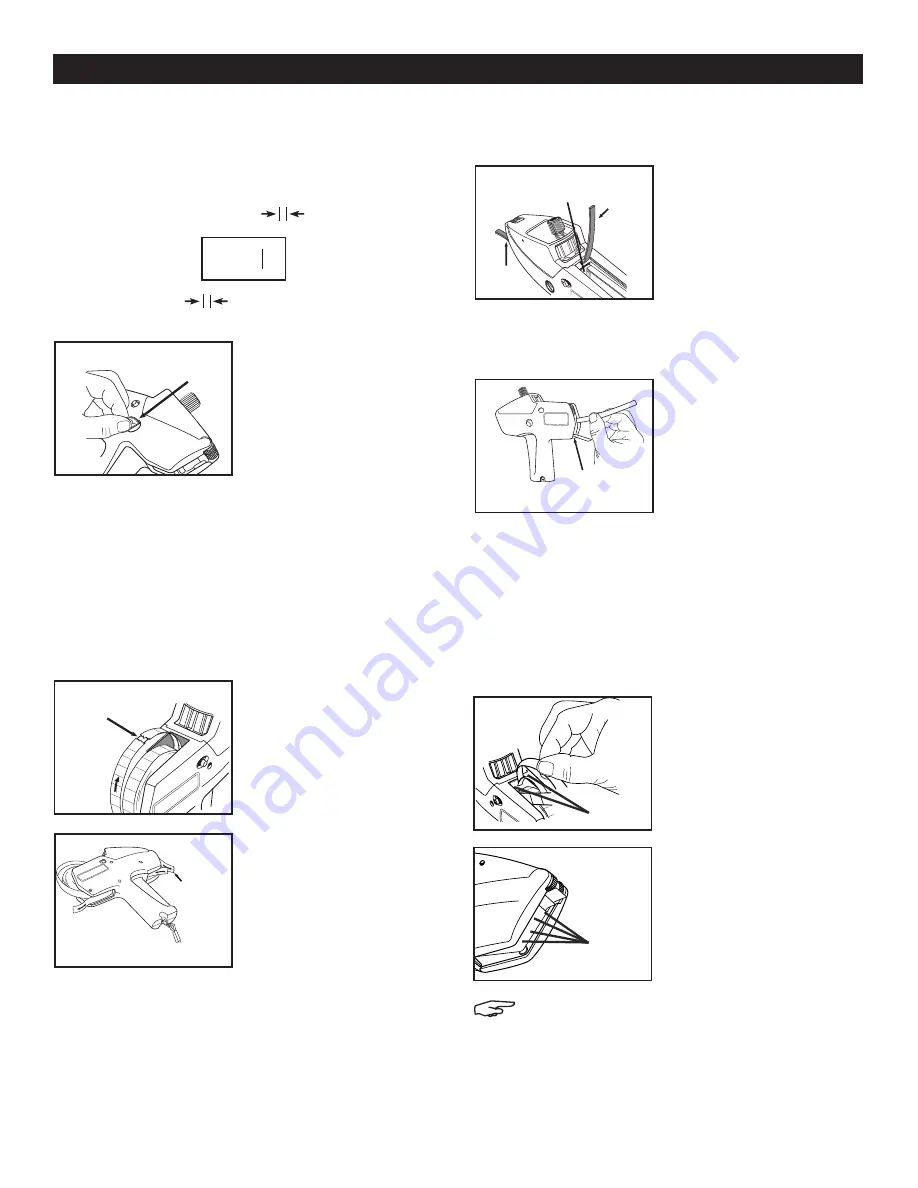

LUBRICATE

PRINT ADJUSTMENT

1. Print location is correct when extreme righthand and

lefthand characters are located as shown.

2.

Place small coin in

feedwheel button slot.

(See Figure 9)

3. Push feedwheel button in completely and turn

slightly clockwise if print is too far left or slightly

counterclockwise if print is too far right. Adjustments

made without completely depressing button are

temporary.

4. Repeat steps 2 and 3 until print is correctly

aligned.

REMOVE SUPPLIES

1. Tear label strip at label

roll as shown and pull

label roll from between

hubs. (See Figure 10)

2.

Tear backing paper

strip. Pull label strip

from labeler. (See

Figure 11)

3.

Squeeze and release

trigger until backing

paper is free to be

pulled out. (See

Figure 11)

CLEAR JAMS, CLEANING AND

LUBRICATION

1.

With label roll removed,

check label track and

backing paper track

for stray labels.

2. Clear label track by squeezing trigger and feeding

label removal strip under brake wheels and out front

of labeler. (See Figure 12)

3.

To clear backing

paper track:

a. Insert label removal

strip in end of track

to loosen stray

labels. (See

Figure 13)

b. Insert label removal

strip as shown,

using corner to

remove stray labels.

(See Figure 13)

4. If adhesive buildup occurs, lubricate with one drop

of a commercial 100% silicone lubricant as shown

with labels loaded.

LUBRICATE

One drop each side of

label chute between

spring and backing

paper. (See Figure 14)

LUBRICATE

One drop each spot

on backing paper

(total of four drops).

Spread with finger.

(See Figure 15)

NOTE: DO NOT OVER LUBRICATE!

LUBRICATE

FRONT

EXIT

BRAKE

WHEELS

REMOVAL

STRIP

Figure 12

Figure 14

Figure 15

FEEDWHEEL

BUTTON SLOT

Figure 9

INSTRUCTIONS CONTINUED

END OF

TRACK

Approx. 1/16 inch (1.6 mm)

Approx. 1/16 inch (1.6 mm)

FOR

+TX

99

3

c

TEAR

Figure 10

TEAR

BACKING

PAPER

Figure 13

Figure 11