2

Twin City Engineering Supplement 895

cause premature belt or drive replacement. If burrs are

found, use fine emery cloth or a stone to remove them.

Be careful that dust does not enter the bearings.

Check sheaves for wear. Excessive slippage of belts

on sheaves can cause wear and vibration. Replace worn

sheaves with new ones. Carefully align sheaves to avoid

premature sheave failure.

Inspect the belts for wear. If fraying or other wear is

observed to be mostly on one side of the belts, the

drives may be misaligned. Reinstall the drives according

to the following instructions:

1. Slip (do not pound) proper sheave onto corresponding

shaft.

CAUTION:

Placing fan sheave on motor can over-

speed wheel and cause structural failure.

2. Align sheaves with straightedge extended along

sheaves, just making contact in two places on out-

side perimeters of both sheaves.

3. Tighten sheave bolts (or setscrews if appropriate).

Table 1 can be used to determine the amount of

torque required.

4. Install a matched set of belts. Adjust the motor posi-

tion to obtain slack, install, and tighten belts. Using

a pry bar will damage belts.

5. Tighten belts to proper belt tension. Ideal tension is

just enough so that the belts do not slip under peak

load. When using drive tensioning data supplied by

V-belt drive manufacturers, new belts can be tensioned

to a value 50% greater than for normal operation. This

will reduce retensioning requirements after break-in.

Recheck sheave alignment after tensioning.

6. After initial installation of belts, recheck belt tension

again after a few days. (New belts require a break-in

period of operation.)

7. When replacing belts, replace the entire set. After initial

replacement and tensioning, recheck belt tension after

a few days. (New belts require a break-in period of

operation.) Never use belt dressing on any belts.

8. Fans that have motors and drives mounted at the

factory are trim balanced prior to shipment. This is

not possible on units that are shipped without motors

and drives. The addition of drive components in the

field can create unbalance forces. Twin City Fan &

Blower recommends final balancing of the unit after

the drive components are installed. Failure to do so

may void the warranty.

Motor Support Adjustment

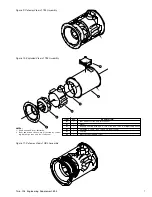

Two different types of motor mounts, post and saddle,

are used on TSL Inline Centrifugal and QSL Mixed Flow

fans. Which mount to use depends on the size of the fan

and motor.

On the post type motor mount, the motor plate is

supported on four threaded rods. Belt tension is adjust-

ed by loosening the four nuts on top of the motor plate

and raising the motor plate by adjusting the four nuts

underneath it. The top nuts should then be tightened to

hold the motor plate in place.

On the saddle type motor mount, the motor pivots

on one side and adjustment of belt tension is achieved

by loosening the nuts on top of the motor plate on the

other side, then raising the motor plate by adjusting the

nuts underneath the motor plate. The nuts on top of the

motor plate should again be tightened to hold the motor

plate in place. Several holes are provided on the pivot

side, and the pivot point can be raised for gross belt

adjustment. If this adjustment is made, however, the

motor plate should be as parallel as possible to the fan

centerplane. Care should be taken to maintain drive

alignment and proper belt tension.

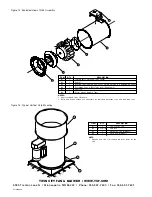

Bearing Maintenance

Proper lubrication of the fan drive bearings helps assure

maximum bearing life. All fans are equipped with decals

indicating relubrication intervals for normal operating

conditions. See Figures 2, 3 and 4 for typical lubrication

data. However, every installation is different and the

frequency of relubrication should be adjusted accord-

ingly.

On high moisture applications, the lubrication fre-

quency may need to be doubled or tripled to adequate-

ly protect the bearings. Double the relubrication fre-

quency on fans with vertical shafts.

Observation of the conditions of the grease expelled

from the bearings at the time of relubrication is the best

guide as to whether regreasing intervals and amount of

grease added should be altered.

Greases are made with different bases. There are

synthetic base greases, lithium base, sodium base, etc.

Avoid mixing greases with different bases. They could

be incompatible and result in rapid deterioration or

breakdown of the grease. The lubrication sticker identi-

fies a list of acceptable lubricants. All bearings are filled

with a lithium-based grease before leaving the factory.

When the fans are started, the bearings may discharge

excess grease through the seals for a short period of

time. Do not replace the initial discharge because leakage

will cease when the excess grease has worked out.

Sometimes the bearings have a tendency to run hotter

during this period. There is no reason for alarm unless

it lasts over 48 hours or gets very hot (over 200°F). When

relubricating, use a sufficient amount of grease to purge

the seals. Rotate bearings by hand during relubrication.

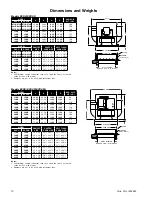

Table 1. Tightening Torque (Ft.-Lbs.)

Tolerance: +5%

For wheel setscrews use Grade 2 values. The above torque values are for nonlubricated fasteners.

SIZE

FASTENER

TAPER BUSHINGS

GRADE 2

GRADE 5

GRADE 8

BROWNING SPLIT

QD

FOR DRIVE

IN IRON

IN ALUM. HUB

#10

—

—

—

—

—

5

1

⁄

4

-20

5.5

8

12

7.9

7.5

9

5

⁄

16

-18

11

17

25

16

13

15

3

⁄

8

-16

22

30

45

29

24

30

7

⁄

16

-14

30

50

70

—

—

—

1

⁄

2

-13

55

75

110

70

—

60

9

⁄

16

-12

—

—

—

—

—

75

5

⁄

8

-11

100

150

220

—

—

135

3

⁄

4

-10

170

270

380

—

—

—

7

⁄

8

-9

165

430

600

—

—

—

1-8

250

645

900

—

—

—

1

1

⁄

4

-7

500

1120

1500

—

—

—